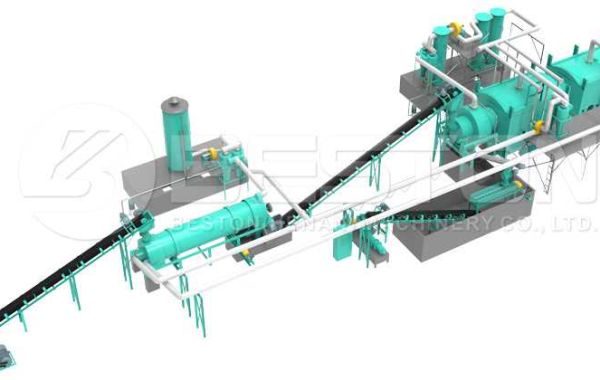

Charcoal making machine is designed to produce charcoal with higher carbon content. This is a continuous process as well as the end product is generally a briquette that is 83% carbon. The screw area of the charcoal making machine for sale can improve the quality of the very last product. You can use it for a wide range of production processes, including firewood. You can choose the particular briquetting device that fits your requirements and preferences. Listed below are some great benefits of briquetting machine.

Firstly, this machine can be used to make biomass waste matter into charcoal. It uses the pyrolysis process under an oxygen-free environment to create char. It is a terrific way to conserve resources while gaining good profits. Along with its resource utilization, this machine can be found in different kinds. The Beston group continues to be manufacturing charcoal making plant for quite a while. The company's professional team and advanced technology have the equipment energy-saving and it has excellent support service. The cost for this particular gear is reasonable and varies dependant upon the sort of machine you require. See the small charcoal making machine here.

The ideal batch charcoal making machine is surely an energy-efficient one who meets the emission standards of many countries. It possesses a high production rate and low energy consumption, so it is a fantastic investment for smaller businesses. The business has several the latest models of of charcoal making machines. The Beston charcoal making machine features a built-in dust removal system that mixes ocean ball adsorption, water spray, and activated carbon. Furthermore, the gear complies with national emission standards and employs a ceramic fiber combustion chamber in order to avoid secondary pollution of castable and guarantees a 12-year service life. In addition, it incorporates intelligent control and frequency conversion technology, rendering it energy-efficient.

The most significant feature of a good biochar machine for sale is its heat-use ratio. During the process of burning raw materials, the temperature must rise above 180°C. Then, the moisture content articles are less than 15%. Employing a dryer is important in the event the materials contain a lot more than 15% water. The materials that enter the reactor have been heated. As the temperature rises, oil gas will be generated. The fabric will likely burn continuously to create charcoal. The auto screw discharger will give you the charred charcoal to the charcoal tank. The tar and wood vinegar will probably be collected in separate tanks.

The Beston charcoal making machine is energy-saving and eco-friendly. It uses advanced biomass pyrolysis technology and can be used as small-scale or industrial applications. The Beston equipment is compatible with a variety of biomass waste, sludge, and food waste. It is equipped with an automated screw discharger as well as a drying system. The charred material will likely be delivered to the charcoal tank. The wood charcoal is a great fuel source.

A charcoal making machine has numerous benefits of incorporating your organization. However, the most convenient to view is when it can add probability and growth. In case you have been looking for the best easy way to expand your business, please get in touch with us to talk about the addition of a biochar production equipment.