TWS battery injection has always been a difficult point. Recently, in response to the difficult problem of TWS battery injection, Guangzhou Ascend Precision Machinery has launched a high vacuum liquid injection system, which effectively promotes work efficiency.

TWS headset batteries are mainly: small steel shell batteries and button batteries. The battery is small in size, the injection volume is generally 0.1-0.6g, the injection accuracy is high (±0.005g), the injection caliber is small (1.2mm or less), the cell density is high, the electrolyte is difficult to absorb, and the injection is difficult It is very large, so the vacuum injection method is often used for injection.

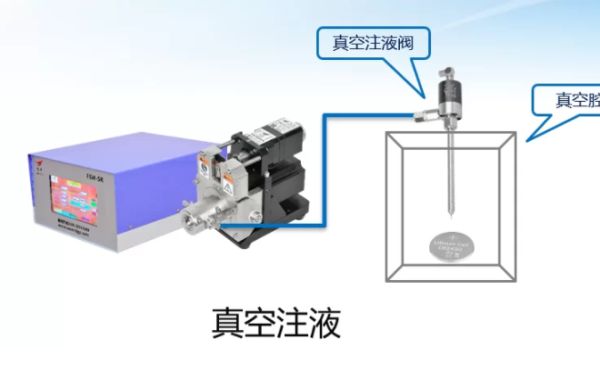

Aiming at the difficult problem of TWS battery injection, Guangzhou Ascend Precision Machinery has launched a high vacuum injection system, which is composed of FSH-SKAP or FSH-SK08 series precision ceramic injection pump and FSH-VLIV series vacuum injection valve. The battery is directly filled with liquid under vacuum-95Kpa environment, and the accuracy of liquid filling is guaranteed.

Different from the traditional liquid filling method of liquid filling cup, Ascend Precision Machinery 's high vacuum liquid filling system can directly inject liquid into TWS battery under vacuum condition, which has the following advantages:

1. High precision, Ascend Precision Machinery uses direct injection instead of the liquid injection cup method, which has higher accuracy, and the CV value is as high as 0.3%;

2. Intelligent micro-adjustment of liquid injection volume can accurately realize online closed-loop control of micro liquid injection volume;

3. High-precision ceramics can achieve micro-dispensing, ranging from μL to ml-level, which fully meets the micro-dispensing of TWS batteries.

4. The diameter of the vacuum valve can be customized according to the injection diameter (1.2mm or less)

5. Maintenance-free design, direct liquid injection to eliminate intermediate links, greatly reducing the failure rate, and the production line can run for 24 hours to increase production capacity;

6. High-vacuum liquid injection can be as high as -95KPa for direct liquid injection, which can increase the electrolyte absorption rate and increase production capacity.

Guangzhou Ascend Precision Machinery Co., Ltd. is a high-tech enterprise specializing in fluid precision control systems and solutions. The company has extremely rich experience in the field of micro-fluid injection, dispensing, spraying, and automation design and manufacturing.

Since 2016, Ascend Precision Machinery has provided on-site batch vacuum injection solutions (0 to -95kpa) to a large number of well-known lithium battery companies, with no dripping, high precision, and the CPK value continues to be stable.

Ascend Precision Machinery integrates excellent RD, design, production and sales to provide customers in multiple industries with trace fluid control injection, filling, spraying, metering, line drawing and dispensing and automation equipment. Energy lithium batteries, biochips, pharmaceuticals, medical devices, and semiconductors provide industry-leading system solutions. At present, many products of the company have obtained invention and utility patents issued by the state.

This time, the high vacuum liquid injection system launched by Guangzhou Ascend Precision Machinery has effectively solved the difficult problem of TWS battery liquid injection. Ascend Precision Machinery adheres to the core concept of "professionalism, focus, innovation, and efficiency", adheres to the never-ending technology, and will continue to invest in research and development technology, continue to lead the injection pump technology and development route, grow together with customers, and provide customers with safety and efficiency Solution for injection.