CNC machining has the following advantages:

① The number of tooling is greatly reduced, and complex tooling is not required to process parts with complex shapes. If you want to change the shape and size of the part, you only need to modify the part machining program. It is very suitable for new product development and modification.

②Stable processing quality, high processing precision and high repeatability.

③ The production efficiency is higher in the case of multi-variety and small batch production.

④ It can process complex profiles that are difficult to process by conventional methods, and even process some unobservable processing parts.

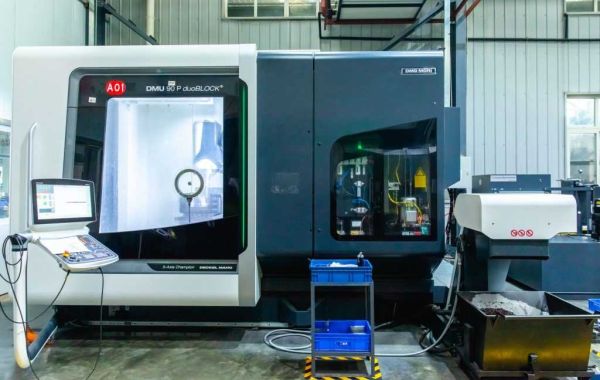

General CNC machining usually refers to computer digital control precision machining, CNC machining lathes, CNC machining milling machines, CNC machining boring and milling machines, etc.

The disadvantage of CNC machining is that the machine tool is expensive and requires a high level of maintenance personnel.

Application of CNC machining:

- CNC numerical control lathe processing is most suitable for multi-variety small and medium-sized parts.

⒉Suitable for CNC lathes with high precision requirements. Due to the good rigidity of CNC lathe processing, high manufacturing precision, accurate tool setting, and convenient dimensional compensation, it can process parts with high dimensional accuracy requirements.

- CNC lathes process parts with small surface roughness values.

In the case of constant workpiece and tool material, finishing allowance and tool angle, the surface roughness depends on the cutting speed and feed rate. When machining surfaces with different surface roughness, a small feed rate is used for the surface with small roughness, and a larger feed rate is used for the surface with large roughness, and the variability is very good.

- Suitable for parts with complex contour shapes. Any plane curve can be approximated by straight lines or arcs, and CNC lathes can process parts with various complex contours.

You can contact JTR to provide you with excellent CNC machining services.