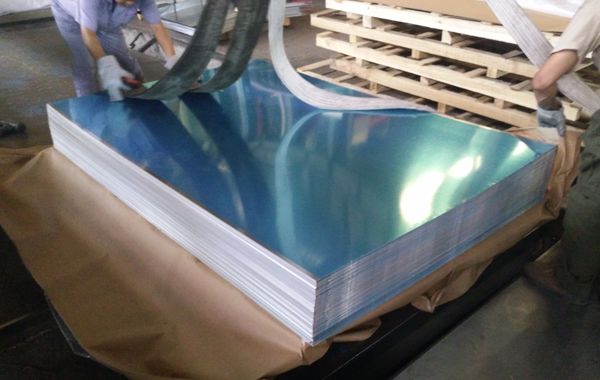

Aluminum cladding sheet stucco embossed for insulation are widely used, effective, cheap, simple and convenient to use. By using stucco 4×8 Aluminum Sheet, we can get good results whether they are used in production or in daily life, only in this way can there be a more robust, compact, long-lasting, and durable insulation system. Pipe aluminum cladding sheet insulation is not only a normal transportation method for providing heating pipes, but also has a certain safety effect, so you are completely relieved.

Pipeline insulation engineering is the protection of pipelines outside the ground or underground. The pipelines can easily cause damage to the pipelines directly in the air for a long time. In addition, some special pipelines such as heating pipelines need to be insulated and protected. The aluminum cladding sheet stucco insulation construction of the pipeline is to apply one or several protective layers to the pipeline to prevent the pipeline from being corroded by air and corrosive substances, and at the same time to ensure that the liquid substance conveyed in the pipeline will not be affected by the cold air. Good materials usually have better thermal insulation performance and are widely used, which have the effect of promoting energy saving and thermal insulation.

Aluminum cladding sheet stucco insulation is a kind of insulation measure that can reduce the energy loss of pipelines, including cold and warm pipelines. It has been successfully applied to the chemical, food, energy and other industries, saving users up to 50% of the overall operating cost (electricity cost) Steam cost, equipment failure cost, equipment maintenance cost, equipment update cost, system capacity increase cost), has won universal recognition and praise from users. According to the actual installation case, the energy-saving effect is obvious, and the energy-saving rate can reach 30%-70%, which saves a lot of electricity costs for customers, improves production efficiency, and improves the workshop environment!

Search

Popular Posts