What distinguishes electroplated nickel, electroplated chromium, and electroplated zinc?

- Distinct goals

(1) Chrome plating comes in two varieties: one for aesthetic purposes and the other to boost hardness.

(2) The major purposes of galvanizing are anti-corrosion and attractive appearance.

(3) The main purposes of nickel plating are to increase corrosion and wear resistance.

- Prices differ

The most expensive of the three electroplating techniques is chrome plating, which is followed by nickel and zinc.

- A variety of colors

(1) Galvanized has a silver-white look.

(2) Nickel plating has a silvery white look with some yellow undertones.

(3) Hard chrome and decorative chrome plating both have a bright white with bluish undertone to them.

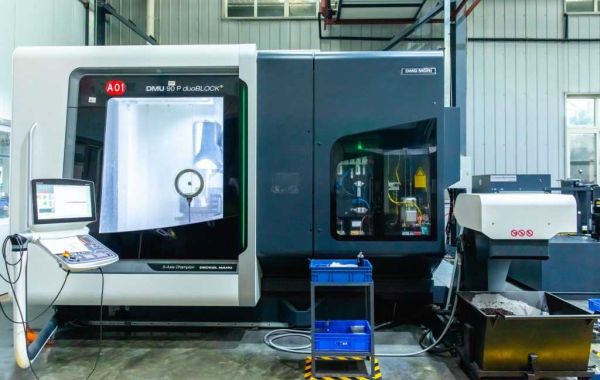

The three popular electroplating methods and their distinctions are briefly discussed above. JTR is able to offer a range of surface treatment services, including several types of electroplating procedures, as a professional manufacturer committed to offering high-quality rapid prototyping and mass manufacturing services. We can tailor the best manufacturing solution to meet your needs since we have a thorough understanding of the distinctions and traits of various manufacturing processes. Please feel free to contact us if you require it.