A scroll chuck, also known as a lathe chuck, is a vital tool used in metalworking and machining processes. Its primary function is to securely hold and center workpieces on a lathe or rotary machine, allowing for precise and controlled material removal or shaping.

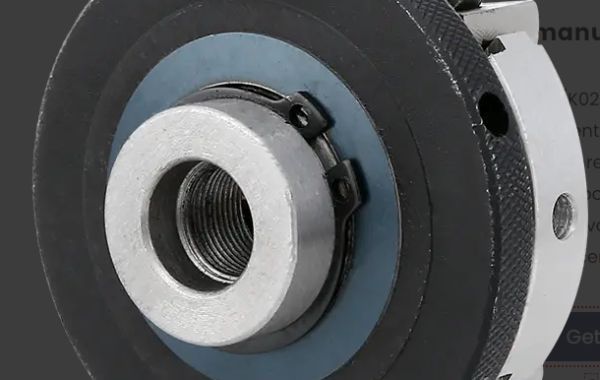

One of the key features of a scroll chuck is its self-centering mechanism. Inside the chuck, there is a scroll plate with multiple sets of jaws. As the chuck is tightened, the scroll plate engages, causing the jaws to move simultaneously and center the workpiece. This automatic centering simplifies the setup process and ensures that the workpiece is held securely and accurately.

Scroll chucks come in various sizes and configurations, making them suitable for a wide range of workpiece dimensions and shapes. Three-jaw scroll chucks are commonly used for holding cylindrical workpieces, while four-jaw scroll chucks provide greater flexibility for irregularly shaped or non-symmetrical workpieces.

The design of scroll chucks allows for quick and easy workpiece changes, reducing downtime and increasing productivity. This makes them popular choices in industries such as metalworking, woodworking, and manufacturing, where efficiency and precision are paramount.

Additionally, scroll chucks are known for their durability and stability, ensuring that they can withstand the rigors of machining operations. Their ability to securely grip workpieces while maintaining concentricity contributes to the quality and accuracy of finished products.

In conclusion, the scroll chuck is an indispensable tool in machining and metalworking, providing automatic centering, versatility, and durability. Its ability to securely hold workpieces and facilitate quick changes makes it a valuable asset in various industrial applications.