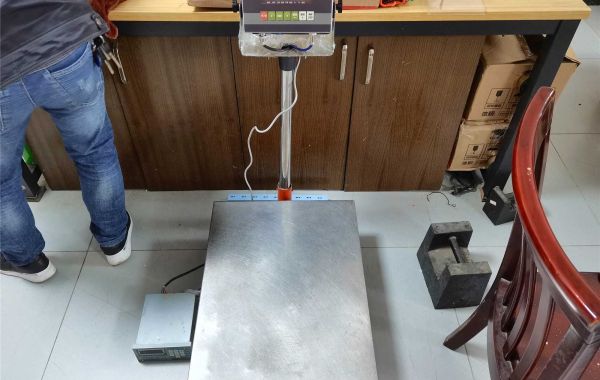

Absolutely, maintaining the safety features of explosion-proof electronic scales is crucial for their continued safe operation in hazardous environments. Here are some specific maintenance procedures you should follow:

Regular Inspections

- Visual Inspection: Regularly inspect the explosion-proof enclosure for any signs of damage, cracks, or corrosion. Pay close attention to welds, seams, and areas around access points like doors or cable connections. Any compromised areas could potentially compromise the integrity of the seal and allow hazardous materials to enter.

- Internal Component Inspection (by Qualified Personnel):While you can perform visual inspections, some internal components like flame arrestors or intrinsically safe circuits might require inspection by a qualified technician. They can use specialized tools and procedures to ensure these components are functioning correctly and haven't degraded over time.

Cleaning and Maintenance

- Cleaning Procedures:Follow the manufacturer's recommended cleaning procedures for the specific scale model. Avoid harsh chemicals or abrasive cleaning methods that could damage the explosion-proof enclosure or its special seals. Use appropriate cleaning solutions suitable for the hazardous materials the scale is exposed to and ensure proper drying to prevent corrosion.

- Seal Maintenance:Regularly inspect the seals around cable connections, access points, and the weighing platform for any signs of wear, tear, or cracking. These seals are vital for preventing the ingress of hazardous materials. Replace any damaged seals promptly with manufacturer-approved replacements to maintain the integrity of the enclosure.

Calibration and Documentation

- Regular Calibration:Maintain a regular calibration schedule for your explosion-proof electronic scale, just like you would for any standard weighing scale. This ensures the accuracy of the weight measurements. Consult the manufacturer's recommendations and any relevant industry regulations for the appropriate calibration frequency.

- Detailed Documentation:Maintain a logbook to document all maintenance activities performed on the explosion-proof scale, including inspections, cleaning, seal replacements, and calibrations. This record-keeping demonstrates adherence to safety protocols and helps identify any potential issues that might require further attention.

Additional Considerations

- Training for Operators:Ensure that anyone operating the explosion-proof scale is properly trained on its safe use and basic maintenance procedures. This includes understanding the potential hazards in the environment and how to identify any signs of damage or malfunction on the scale.

- Following Regulations:Always adhere to any relevant regulations or industry standards that apply to the use of explosion-proof electronic scales in your specific hazardous environment.

By following these specific maintenance procedures and adhering to best practices, you can ensure the continued safety and reliability of your explosion-proof electronic scales. Remember, even a minor oversight in maintenance can compromise the safety features and put personnel and the surrounding environment at risk.