A progressive cavity pump is a type of positive displacement pump and is also known as a progressing cavity pump, prog cavity pump, eccentric screw pump, or cavity pump. When its rotor rotates, it transports fluid through the pump through a series of small, fixed-shaped, discrete cavities. This causes the volume flow to be proportional to the rate of rotation (bidirectional) and applies a low level of shear to the pumped fluid.

These pumps are often used for fluid metering and shearing materials. Each cavity tapers toward its end and overlaps. As one cavity decreases and the other increases, the change in net flow is minimal because the total displacement is equal. This design results in almost no pulses in the flow.

Theory

The progressive cavity pump normally consists of a helical rotor and a twin helix, twice the wavelength helical hole in a stator. People often misunderstand how this pump works. It is generally believed that the work of the Progressive cavity pump is caused by dynamic effects caused by resistance or friction with the moving teeth of the screw rotor. In fact, this is because the sealed cavity has similar working characteristics as the piston pump, for example, it can pump at a very low rate or even high pressure, thus exhibiting a pure positive displacement effect. The rotor "climbs" the inner cavity in an orbital manner.

When the rotor rotates, it rolls/climbs around the inner surface of the hole. The movement of the rotor in the Progressive cavity pump is the same as the planetary gears in the planetary gear system. When the rotor rotates and moves at the same time, the combined movement of the installed drive shaft is in the form of a hypocycloid. In the typical case of a single helical rotor and a double-helical stator, the hypocycloid is just a straight line. The rotor must be driven by a set of universal joints or other mechanisms to allow eccentricity.

What purposes do progressive cavity pumps serve?

Screw pumps are used to pump fluids that other types of industrial pumps cannot handle. They are generally used for the following purposes.

- Pumping, metering, and metering chemicals

- Pump fluids in applications requiring different flow rates

- Pumping materials containing abrasive particles

- Pumping shear sensitive materials

- Pumping heavy or viscous fluids

Usually, screw pumps are used in the following areas.

- metering and dosing

- wastewater

- chemical manufacturing

- oil pumping/petroleum production

- limited energy well water pumping

- lubrication oil pumping

- pulp and paper

- environmental technology

- sewage, sludge, and slurry pumping

- grout or cement pumping

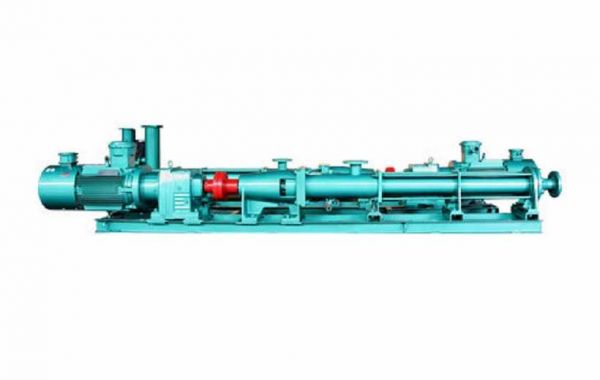

Types of progressive cavity pumps

Common screw rods are single screw pumps, twin screw pumps, and triple screw pumps. The choice of pump lies in the material to be pumped and the required flow rate of the pumped material.

Chongqing Mingzhu ME Co., Ltd. Located in western strategic highland- Chongqing Xiyong Micro-electronics Industrial Park, is a state-recognized high-tech enterprise, specializing in RD, production, sales, and service of screw pumps, rotor pumps, water injection pumps, and skid-mounted integrated devices, and other related product. We are one of the standard-setting units of China's single screw pump industry, and our technology is in a leading position in China. In addition to conventional screw pumps, we also provide customers with customized services to produce perfect screw pumps for you.