This blog post will discuss the key factors to consider when selecting downhole equipment for optimal performance.

- Wellbore Conditions

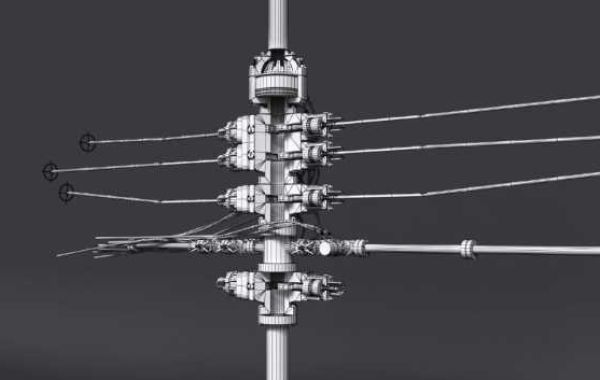

Depth and temperature: The depth and temperature of the wellbore will significantly impact the equipment's design and materials. Deeper wells and higher temperatures require equipment that can withstand extreme conditions.

Pressure: The pressure within the wellbore, including bottom hole pressure and casing pressure, must be carefully considered to prevent equipment failure.

Formation properties: The properties of the formation, such as porosity and permeability, will influence the type of equipment needed for effective production.

- Drilling Fluid

Type and properties: The drilling fluid used in the wellbore will interact with the downhole equipment. Factors like pH, density, and viscosity must be considered to ensure compatibility and prevent corrosion.

Solids content: High solids content in the drilling fluid can cause wear and tear on downhole equipment. Selecting equipment that can withstand abrasive conditions is essential.

- Production Objectives

Well type: The type of well, such as vertical, horizontal, or deviated, will determine the specific requirements for downhole equipment.

Production rate: The desired production rate will influence the size and capacity of the equipment needed.

Reservoir characteristics: The characteristics of the reservoir, such as fluid type and flow dynamics, will impact the selection of downhole equipment.

- Regulatory Compliance

Local and international regulations: Downhole equipment must comply with relevant local and international regulations to ensure safety and environmental protection.

Industry standards: Adherence to industry standards, such as API and ISO, can help guarantee the quality and reliability of the equipment.

- Cost-Effectiveness

Initial investment: The initial cost of downhole equipment can vary widely depending on the type and complexity.

Long-term costs: Consider the long-term costs associated with maintenance, repairs, and potential downtime.

Return on investment: Evaluate the potential return on investment by assessing the equipment's expected performance and contribution to overall production.

- Supplier Reputation and Support

Experience and expertise: Choose a supplier with a proven track record in providing high-quality downhole equipment.

Technical support: Ensure the supplier offers reliable technical support and assistance throughout the equipment's lifecycle.

After-sales service: Consider the availability of after-sales services, such as spare parts and repair services.

By carefully considering these factors, you can select downhole equipment that is well-suited to your specific drilling and production needs, ensuring optimal performance and maximizing your return on investment.