The thermal management of electronic components is a critical aspect of modern technology, and the Aluminum Profile Heatsink plays a significant role in this process. The ability of an Aluminum Profile Heatsink to dissipate heat effectively is directly related to its surface area, which is a fundamental parameter in determining its cooling capacity. The larger the surface area of an Aluminum Profile Heatsink, the greater its potential to transfer heat away from the source, thereby maintaining the optimal operating temperature of the electronic components.

The science behind this phenomenon is rooted in the principles of heat transfer, specifically conduction and convection. When an Aluminum Profile Heatsink is in contact with a heat-generating component, such as a CPU or a power transistor, it absorbs heat through conduction. The Aluminum Profile Heatsink's large surface area allows for a greater contact area with the surrounding air, which facilitates more efficient heat dissipation through convection. As the heat is spread over a larger area, the temperature gradient across the Aluminum Profile Heatsink increases, enhancing the rate at which heat is transferred to the air.

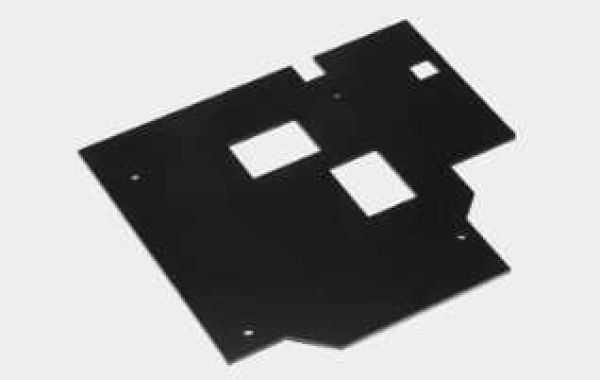

Moreover, the design of the Aluminum Profile Heatsink also plays a crucial role in maximizing the benefits of its surface area. Fins or other extended structures can be added to the Aluminum Profile Heatsink to increase its surface area without significantly increasing its volume. These fins provide more surface for the air to come into contact with, thereby increasing the rate of heat transfer. The shape and orientation of these fins can also be optimized to take advantage of natural convection currents, further improving the Aluminum Profile Heatsink's cooling performance.

However, it is important to note that while a larger surface area generally leads to better cooling, it is not the sole determinant of an Aluminum Profile Heatsink's effectiveness. The material properties of the aluminum used, such as its thermal conductivity, also play a significant role. Aluminum is a popular choice for heatsinks due to its high thermal conductivity, which allows it to quickly transfer heat from the component to the air. Additionally, the thickness and density of the Aluminum Profile Heatsink can affect its ability to store and dissipate heat.

Another factor to consider is the airflow around the Aluminum Profile Heatsink. Even with a large surface area, if the air cannot circulate effectively around the heatsink, the cooling performance will be compromised. This is why fans or other cooling systems are often used in conjunction with Aluminum Profile Heatsinks to ensure that the air is continuously moved across the surface, carrying away the heat and maintaining a lower temperature.

In conclusion, the surface area of an Aluminum Profile Heatsink is a critical factor in its ability to dissipate heat effectively. A larger surface area allows for greater heat transfer through convection, but it must be paired with an efficient design, high thermal conductivity material, and adequate airflow to maximize its cooling potential. By understanding and optimizing these factors, engineers can design Aluminum Profile Heatsinks that provide reliable and efficient thermal management for a wide range of electronic devices.