Preform moulds have played a pivotal role in the production of plastic containers, especially in the beverage industry. Their development traces back to the late 20th century when the demand for lightweight, durable packaging began to rise. The introduction of polyethylene terephthalate (PET) as a preferred material marked a significant turning point. PET’s strength, clarity, and recyclability made it an ideal choice for manufacturers.

The first preform moulds were simple in design and primarily produced basic shapes for bottles. As technology advanced, so did the complexity of the moulds. By the 1980s, manufacturers began employing injection moulding techniques, which allowed for higher precision and efficiency. This process enabled the creation of intricate preform designs, paving the way for the production of more specialized bottles, including those for carbonated beverages.

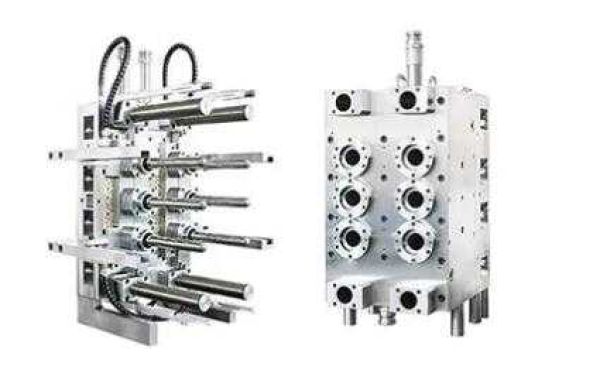

In the following decades, the demand for preform moulds surged as the beverage industry expanded globally. Innovations in moulding technology, such as the development of multi-cavity moulds, further enhanced production efficiency. These advances not only reduced costs but also improved the quality of the final products.

Today, preform moulds are a crucial component in the packaging industry, enabling manufacturers to produce a wide variety of containers quickly and efficiently. As sustainability becomes increasingly important, the evolution of preform moulds will continue, adapting to new materials and technologies to meet future packaging needs.