Key Factors Affecting Aluminium Coil Quality

Alloy Composition:

The specific alloy composition determines the mechanical properties of the aluminium coil, including strength, ductility, and corrosion resistance.

Incorrect alloy composition can lead to reduced performance and premature failure of the final product.

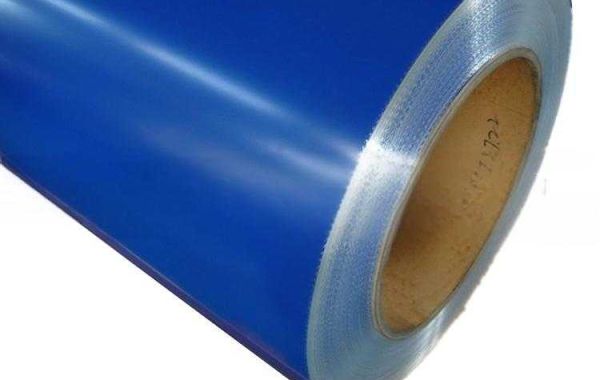

Surface Quality:

The surface quality of the aluminium coil, including smoothness, cleanliness, and freedom from defects, affects the adhesion of coatings and paints.

Poor surface quality can result in uneven coating application, reduced corrosion resistance, and compromised aesthetics.

Thickness Tolerance:

The thickness of the aluminium coil must be within specified tolerances to ensure consistent product performance.

Inconsistent thickness can lead to variations in the final product's strength, stiffness, and weight.

Mechanical Properties:

The mechanical properties of the aluminium coil, such as tensile strength, yield strength, and elongation, are critical for its formability and durability.

Inadequate mechanical properties can result in product failure during manufacturing or in service.

Metallurgical Structure:

The metallurgical structure of the aluminium coil, including grain size and orientation, affects its mechanical properties and formability.

Poor metallurgical structure can lead to reduced ductility and increased susceptibility to cracking.

How Aluminium Coil Quality Impacts Product Performance

Durability and Longevity: High-quality aluminium coils with excellent corrosion resistance and mechanical properties contribute to the long-term durability of the final product.

Aesthetics: A smooth, clean surface finish enhances the appearance of the final product, making it more visually appealing.

Formability: Good formability allows for complex shapes and designs, enabling manufacturers to create innovative and functional products.

Product Performance: Consistent thickness and mechanical properties ensure that the final product meets performance specifications.

Cost-Effectiveness: High-quality aluminium coils can reduce manufacturing costs by minimizing defects and rework.

Conclusion

By selecting high-quality aluminium coils, manufacturers can improve the performance, durability, and aesthetics of their products. It is essential to work with reputable suppliers who can provide consistent quality and adhere to industry standards. By investing in quality aluminium coils, businesses can enhance their brand reputation and gain a competitive edge.