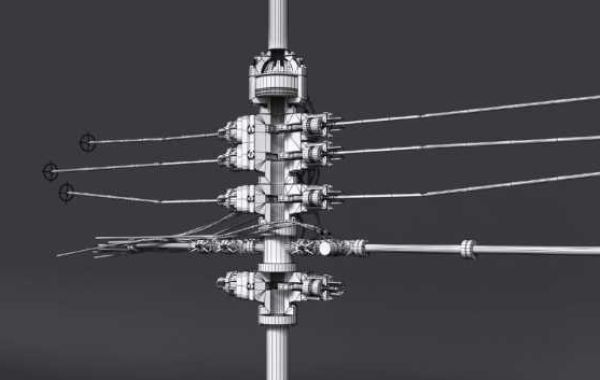

However, with the advent of advanced animation technologies, a new era of interactive and customizable tool assembly simulations has emerged.

The Benefits of Animated Assembly Simulations:

Enhanced Learning: Animated simulations provide a visual representation of the assembly process, making it easier to understand and retain information.

Increased Efficiency: By practicing assembly procedures in a virtual environment, technicians can improve their efficiency and reduce the risk of errors.

Reduced Costs: Virtual training can significantly reduce the costs associated with physical training, such as equipment, labor, and facility rental.

Improved Safety: By simulating potential hazards and accidents, training programs can enhance safety awareness and prevent accidents.

Real-Time Customization for Tailored Training:

One of the most significant advantages of animated assembly simulations is the ability to customize the tools and environments in real-time. This level of customization allows training programs to be tailored to specific tools, operations, and individual learning styles.

Key Customization Features:

Tool Variations: Simulate different tool configurations and sizes to accommodate various operational scenarios.

Environmental Factors: Recreate realistic work environments, including lighting conditions, temperature, and noise levels.

Tool Wear and Damage: Simulate the effects of tool wear and damage to assess their impact on performance and safety.

Interactive Elements: Allow users to interact with the tools, such as adjusting components or performing maintenance tasks.

The Future of Tool Assembly Training

As technology continues to advance, we can expect to see even more sophisticated and immersive assembly simulations. Virtual reality (VR) and augmented reality (AR) will further enhance the training experience, allowing users to step into virtual workshops and interact with tools as if they were physically present.

By embracing these innovative technologies, the oil and gas industry can revolutionize tool assembly training, improve safety, and drive operational efficiency.