Basic Power Supply Demand

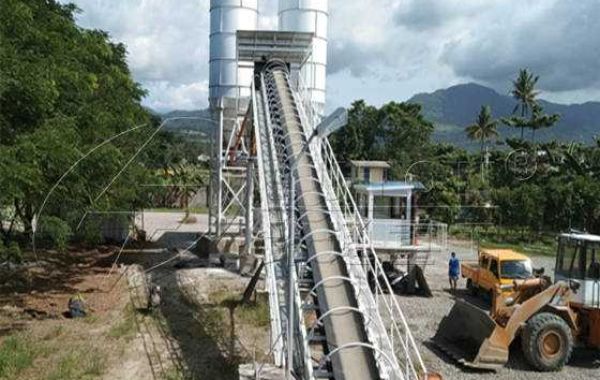

Concrete mixing plants typically consist of key components such as materials storage systems, material weighing systems, material conveying systems, mixing machines and electrical control systems. These systems work together to ensure efficient and stable production of concrete. Among them, the mixing host and electrical control system have the highest power supply requirements because they need to withstand high loads and continuous working pressure.

Classification of Power Supply Methods

The power supply methods for concrete mixing plants are mainly divided into two categories: external grid power supply and self generated power supply.

- External power grid supply

External power supply is the most commonly used power supply method for concrete mixing plants. When the mixing plant is located near the high-voltage power grid, electricity can be directly applied for from the local power grid. This method usually requires the installation of transformers and distribution panels to ensure the stability and safety and current.

The advantages of external power grid supply are stable electricity and low cost. However, it also has certain limitations. For example, when the power grid supply is unstable or during peak periods of concentrated agricultural electricity consumption, voltage fluctuations or power outages may occur, which can affect the normal operation of the mixing plant.

- Self Provided Power Generation And Supply

Self generation power supply is mainly used in areas far away from the power grid or where the power grid supply is unstable. The mixing plant needs to establish a complete power supply system, including generators, distribution panels, and corresponding cable lines.

The advantages of self generated power supply are strong independence and high reliability. Even if there is a power outage in the grid, the mixing plant can continue to supply power through its own generator, ensuring the continuity of production.

However, this approach also has the disadvantages of high cost and complex maintenance. The purchase, installation and operation costs of generators are relatively high, and they require regular maintenance and upkeep.

Emergency Power Supply Measures

In order to ensure the normal operation of the concrete mixing plant in the event of a sudden power outage, emergency power supply measures are usually required. These measures include:

- Emergency Power Supply

Set up backup power sources in the distribution room, such as backup generators. When the main power supply fails, the backup power supply can be quickly connected to provide power support for the mixing plant.

- Segmented Power Supply

Divide the power system of the mixing plant into multiple independent parts, such as the living and office area, concrete mixing area, sand and gravel area, etc. Each part has an independent power supply and distribution box to ensure that other parts can still be powered normally in the event of a local power outage.

- Power Monitoring

Install a power monitoring system to monitor the real-time operation status of the power system. When abnormal situations such as voltage fluctuations and current anomalies are detected, the system can automatically sound an alarm and take corresponding measures to ensure the stability and safety of the power system.

Find more details on concrete batching plant on the website lutonmachinery.com.

Design And Layout Of Power Supply Lines

The design of power supply lines for concrete mixing plants is also an important part of ensuring their normal power supply. In the design process, the following aspects need to be considered:

- Selection of Line Form

Select a suitable route form based on the overall planning scheme of the mixing plant. Usually, a radial distribution line form is adopted, which starts from a centralized power source point and supplies power to each power consumption area separately.

- Route Selection and Calculation

Select appropriate line specifications and quantities based on the load situation of each power consumption area. At the same time, it is necessary to calculate the load of each line to ensure its carrying capacity and safety.

- Cable Selection and Layout

Select appropriate cable types and specifications to meet the transmission requirements of the power system. At the same time, it is necessary to plan the cable layout path reasonably to avoid problems such as cables being too long, too thin, or bent too much, in order to ensure the stability and safety of power transmission.

Summary

The power supply method of the concrete mixing plant is crucial for its normal operation. When choosing a power supply method, it is necessary to comprehensively location, power grid stability, and cost budget. At the same time, emergency power supply measures and reasonable power supply line design and layout plans need to be taken to ensure that the mixing plant can obtain stable and reliable power support in any situation. Only in this way can we ensure the efficient and stable production of concrete mixing plants, and contribute to the sustainable development of the construction industry.