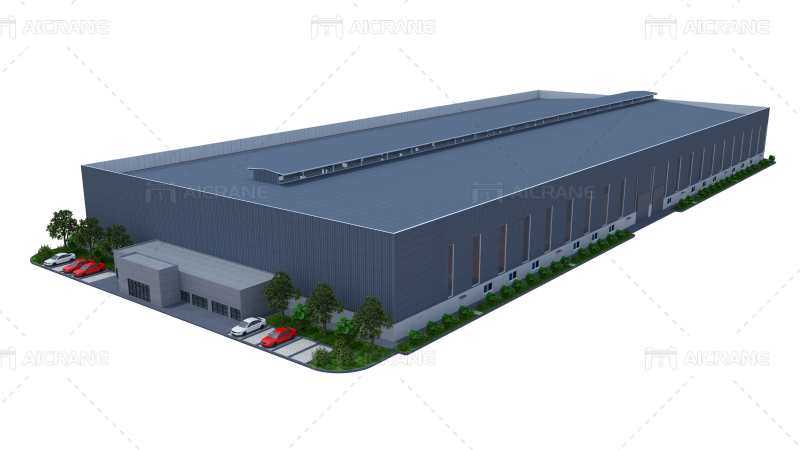

As industries grow and logistics demands evolve, the design and construction of warehouses have seen significant changes in recent years. Steel frame warehouses have emerged as the go-to choice for businesses looking for cost-effective, durable, and adaptable storage solutions. As we move into 2025, the trends shaping steel frame warehouse design and construction are increasingly driven by technology, sustainability, and efficiency. One of the key features of these warehouses is the integration of crane steel structures to improve material handling and operational efficiency. In this article, we will explore the top trends influencing steel frame warehouse design and construction in 2025.

1. Sustainability and Green Building Practices

Sustainability continues to be a major factor influencing the design and construction of steel frame warehouses. In 2025, businesses are more conscious of their environmental impact and are looking for solutions that not only provide cost savings but also adhere to green building standards. Steel frame structures, which are highly recyclable and energy-efficient, align well with these sustainability goals.

Energy-efficient Design

Energy-efficient features, such as insulated panels, solar panels, and energy-saving lighting systems, are becoming increasingly common in steel frame warehouse designs. These features help reduce energy consumption and operational costs over the long term. Additionally, integrating these features can lead to a warehouse that achieves certification for sustainable building practices, such as LEED (Leadership in Energy and Environmental Design), which is becoming a requirement for many businesses.

Recycling and Material Sourcing

Steel is one of the most recycled materials in the world. In 2025, steel frame warehouses are likely to incorporate more sustainable sourcing of materials. Recycled steel and other eco-friendly materials are increasingly being used in construction, reducing the need for new raw materials and lowering the carbon footprint of the building process.

2. Integration of Advanced Automation and Smart Technology

The rise of Industry 4.0 has transformed how warehouses are designed and operated. The integration of automation and smart technology in steel frame warehouses is a trend that is set to continue into 2025. These technologies enable businesses to streamline their operations and improve the speed and accuracy of their workflows.

Automated Storage and Retrieval Systems (ASRS)

Incorporating Automated Storage and Retrieval Systems (ASRS) into steel frame warehouses enhances operational efficiency by automating the storage and retrieval of goods. This reduces the need for manual labor, speeds up inventory management, and minimizes human error. ASRS systems are particularly beneficial in high-volume storage environments, such as those found in e-commerce and distribution centers.

Smart Crane Steel Structures

One of the key trends in 2025 is the use of crane steel structures integrated with automated systems. These smart cranes can be controlled remotely or programmed to perform specific tasks, reducing the need for direct human intervention. The combination of a crane steel structure and automation can drastically improve material handling efficiency, especially in large warehouses with heavy-duty lifting needs. For instance, steel frame warehouses equipped with automated cranes can quickly move heavy pallets or equipment with minimal downtime, improving overall productivity.

IoT Integration

The Internet of Things (IoT) is also playing a key role in smart warehouse design. IoT-enabled cranes, lighting systems, and HVAC controls allow for real-time monitoring and maintenance of equipment. This reduces downtime, improves operational efficiency, and helps warehouse managers keep track of critical data. By utilizing IoT technologies, businesses can achieve better predictive maintenance and operational insights, further reducing costs and increasing productivity.

3. Customization and Scalability

As businesses continue to grow, the need for adaptable and scalable warehouse spaces is more important than ever. Steel frame warehouses are naturally more flexible and easier to expand compared to traditional warehouse buildings, which is one of the reasons they are so popular among businesses that anticipate growth.

Modular Design

The trend toward modular design allows businesses to scale up their steel frame warehouse as needed. Modular steel components are easy to assemble, disassemble, and reconfigure, which is particularly useful for warehouses that need to expand quickly or adapt to new business needs. This scalability allows companies to respond more efficiently to changing market conditions without the need for extensive renovation or new construction.

Customized Crane Systems

The integration of customized crane steel structures is also becoming more common, as businesses require cranes with specific lifting capacities, spans, and functionalities. Whether it's for handling heavy loads in a manufacturing facility or managing bulk storage in a distribution center, custom cranes ensure that material handling operations run smoothly and effectively. These crane systems can be tailored to the unique needs of a warehouse, providing a more streamlined workflow and better support for high-demand environments.

4. Enhanced Safety Features

In 2025, safety remains a top priority in warehouse design and construction. With the increasing complexity of warehouse operations, particularly in steel frame structures, incorporating advanced safety features has become essential.

Seismic-Resistant Steel Structures

In regions prone to natural disasters, such as earthquakes, steel frame warehouses are being designed with seismic-resistant features to ensure structural integrity during extreme conditions. Steel is inherently stronger than many other construction materials, and with the integration of seismic bracing and reinforced joints, steel frame warehouses can withstand seismic activity while keeping workers and inventory safe.

Advanced Safety Systems for Cranes

With the integration of crane steel structures, warehouses are also incorporating advanced safety systems for cranes. These include collision detection sensors, overload protection, and automated shutdown systems that prevent accidents and ensure the safety of both operators and other personnel working in the warehouse. These systems help prevent crane-related accidents, reduce downtime, and minimize the risk of damage to equipment and goods.

5. Cost Efficiency and Faster Construction

As businesses face increasing pressure to cut costs and speed up operations, steel frame warehouses offer significant advantages in terms of cost-efficiency and construction timelines.

Lower Construction Costs

Steel frame warehouses are often less expensive to build than traditional brick-and-mortar warehouses due to the lower material and labor costs associated with steel construction. The quick assembly time of steel frame structures also helps reduce overall construction costs. For businesses looking to establish a warehouse on a tight budget, a steel frame warehouse provides an affordable and efficient option.

Faster Build Times

The modular nature of steel frame construction allows for faster build times, which is especially advantageous for businesses that need to get their warehouse up and running as quickly as possible. Pre-fabricated steel components can be assembled quickly on-site, minimizing delays and getting businesses operational faster.

Conclusion

As we move into 2025, steel frame warehouse design and construction will continue to evolve with the introduction of new technologies, sustainability practices, and customized solutions. Key trends such as the integration of smart technology, automation, and the increasing focus on safety and scalability are transforming how businesses approach warehouse operations. The incorporation of crane steel structures into these designs is further revolutionizing material handling and increasing efficiency in warehouse settings. By staying ahead of these trends, businesses can create more flexible, cost-effective, and productive warehouse environments that are ready to meet the demands of the modern economy.