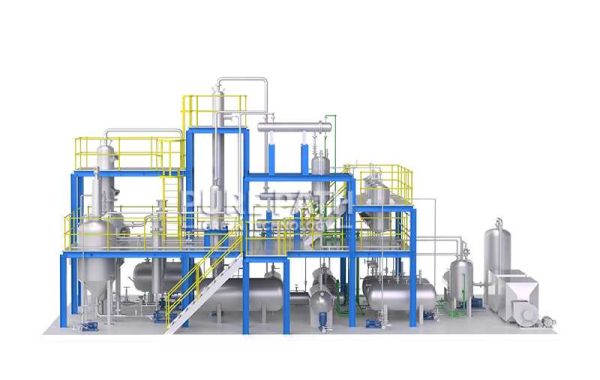

Crude oil refining plants are complex facilities designed to transform raw crude oil into usable products like gasoline, diesel, and jet fuel. Among the many processes involved, catalytic cracking stands out as a critical technology that has revolutionized the industry. This article delves into the importance of advanced catalytic cracking in modern refining plants and how it enhances efficiency and product yield.

Catalytic cracking is a chemical process that breaks down large, heavy hydrocarbon molecules found in crude oil into smaller, more valuable ones. This is achieved by using a catalyst, typically a fine powder composed of zeolites, which facilitates the reaction at high temperatures. The process is essential because crude oil naturally contains a significant portion of heavy hydrocarbons that are not directly useful for most applications.

Modern refining plants have adopted advanced catalytic cracking techniques, such as Fluid Catalytic Cracking (FCC), to maximize efficiency. FCC units are designed to handle a wide range of crude oil feedstocks, including heavier and more challenging types. The process involves injecting the feedstock into a reactor where it meets the catalyst, causing the hydrocarbons to crack into lighter molecules. The catalyst is then regenerated and reused, making the process both cost-effective and environmentally friendly.

One of the key advantages of advanced catalytic cracking is its ability to produce high-octane gasoline, which is in high demand for modern vehicles. Additionally, the process generates valuable byproducts like propylene, a crucial raw material for the petrochemical industry. This dual benefit makes catalytic cracking a cornerstone of refining operations.

However, the process is not without challenges. Catalyst deactivation, caused by the buildup of coke on the catalyst surface, is a common issue that requires frequent regeneration. Refining plants must also manage the heat generated during the process to ensure safety and efficiency. Despite these challenges, ongoing advancements in catalyst technology and process optimization continue to improve the performance of catalytic cracking units.

In conclusion, advanced catalytic cracking is a vital process in modern crude oil refining plants, enabling the production of high-demand fuels and petrochemical feedstocks. As the industry evolves, refining plants will increasingly rely on this technology to meet the growing demand for energy and chemical products.