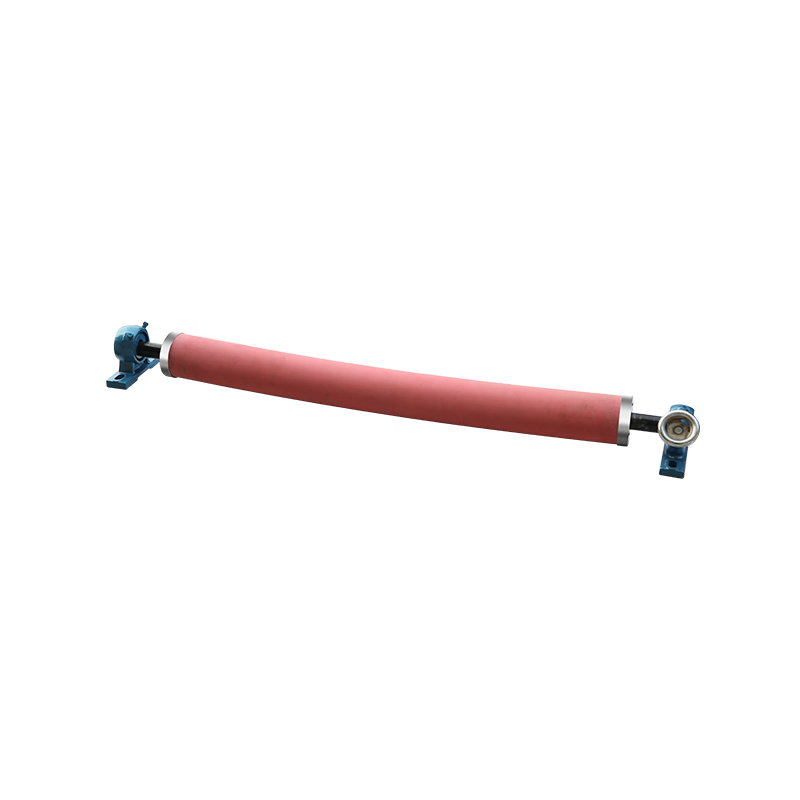

Banana Roller Design are integral to the quality control processes in several manufacturing industries. Their ability to control tension and alignment ensures that the material being processed maintains its structural integrity throughout the production cycle.

In the paper industry, for example, banana rollers are used to ensure the even distribution of paper across the production line. This helps prevent defects such as wrinkles or uneven coatings, which could compromise the quality of the final product. By maintaining consistent pressure and alignment, banana rollers contribute to smoother operation and more uniform material output.

Additionally, banana rollers can assist in reducing material waste. In textile manufacturing, for instance, a misaligned roll of fabric can lead to significant waste. The precision that banana rollers provide ensures that materials are handled efficiently, minimizing errors and reducing costs.

Through the careful design of banana rollers, manufacturers can achieve higher-quality products, increase operational efficiency, and reduce the likelihood of product defects.

https://www.cbbmachine.com/product/banana-roller/customizable-banana-roller.html

| Number | L1 | L2 | L3 | Applicable base material width |

| 1 | 590 | 678 | 730 | 500mm |

| 2 | 725 | 830 | 880 | 600mm |

| 3 | 1175 | 1265 | 1315 | 1100mm |

| 4 | 1220 | 1278 | 1330 | 1100mm |

| 5 | 1500 | 1560 | 1610 | 1320mm |

| 6 | 1435 | 1488 | 1540 | 1320mm |

| 7 | 1760 | 1810 | 1870 | 1600mm |

| 8 | 1805 | 1828 | 1880 | 1600mm |