The aluminum extrusion ( also known by‘aluminum frames’) forming process is a bulk plastic distortion process. First, a billet of aluminum is preheated to a specified temperature that's still comfortably below the material melting point in order to grease the plastic inflow of the material. The heated billet is also forced through a driving bones that's designed to shape and form the billet into the corresponding profile cross section. This artificial extrusion process is similar to the culinary fashion used to make different types of pasta; and also a fashion seen to form shapes in the children’s toy, Play-Doh.

Advantages of Aluminum Extrusion

Aluminum is a veritably generally specified material for use in extrusions and shape profiles because it possesses mechanical characteristics that make it immaculately suited for the shaping and forming essence from billet sections. The high plasticity of aluminum means that the essence can be readily shaped into a variety of sections without expending significant energy on the tooling or forming process, and the melting point of aluminum is also generally on the order of half that of ordinary sword. Both of these data mean that the aluminum extrusion process has a fairly low energy footmark rephrasing into low tooling and manufacturing costs. Eventually, aluminum also possesses a high strength to weight rate, making it an excellent choice for artificial operations.

Types of profiles

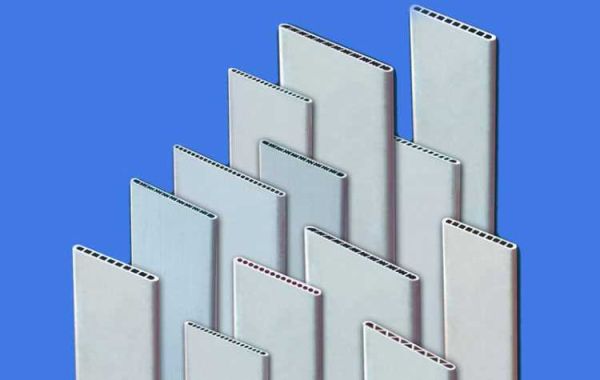

A wide variety of intricate aluminum profile types can be created at varying density. These profiles can feature a wide variety of intricate void spaces, as needed by the end use operation. A wide range of internal voids are available in order to grease a wide variety of robotization operations and also satisfy any performance weight conditions. The most common type of aluminum profile is the concave ray profile which is simply a variation of the square profile. There are also other profile types similar as the triangular, single compass, and L- shaped profile.

img_1013

MISUMI aluminum extrusion profiles. Visitwww.misumiusa.com for a full selection of available profiles, lengths, and face treatments.

Face Types

As a derivate of the extrusion process, there are occasionally small, slightly visible lines present on the shells of the profiles. This is a result of the extrusion tooling, and fresh face treatments can be specified to remove these lines. There are a many of secondary face processing operations that can be performed similar as face milling after the main extrusion forming process in order to ameliorate the face finish of the profile section. These processing operations can be specified in order to ameliorate the figure of the face to ameliorate the part profile by reducing the overall face roughness of the extruded profile. These treatments are generally specified in operations that bear precise positioning of the corridor or where sleeping shells must be controlled tightly. Face treatments can also add fresh erosion resistance, ameliorate the hardness of the profile, or indeed add electrical sequestration to the extrusions.

Black Anodized coating helps cover against erosion, and isnon-conductive.

Black Anodized coating helps cover against erosion, and isnon-conductive.

Uses of profiles Sections

Aluminum profiles are most generally used across artificial robotization operations similar as automated stir operations on process lines and diligence throughout manufacturing. They're strong and yet light enough that they yet can be fluently man- handled and erected into colorful configurations as needed by the robotization structure. Outside of the traditional robotization operations, structural grade aluminum extrusions are indeed being specified as part of weight reduction sweats. In this sense, they're decreasingly being employed as frames in other end use consumer products similar as motorcars and LEED structure systems. As further advanced aluminum blends and face coating ways are developed, the uses are expanding into these new areas.

Conclusion

In ending, extrusion aluminum sections are protean and ideal for use in erecting robotization operations, and aluminum is an excellent structural material which lends itself impeccably for use in profile extrusions. More likely than not, there's an aluminum profile that’s impeccably acclimatized to the specific robotization operation.