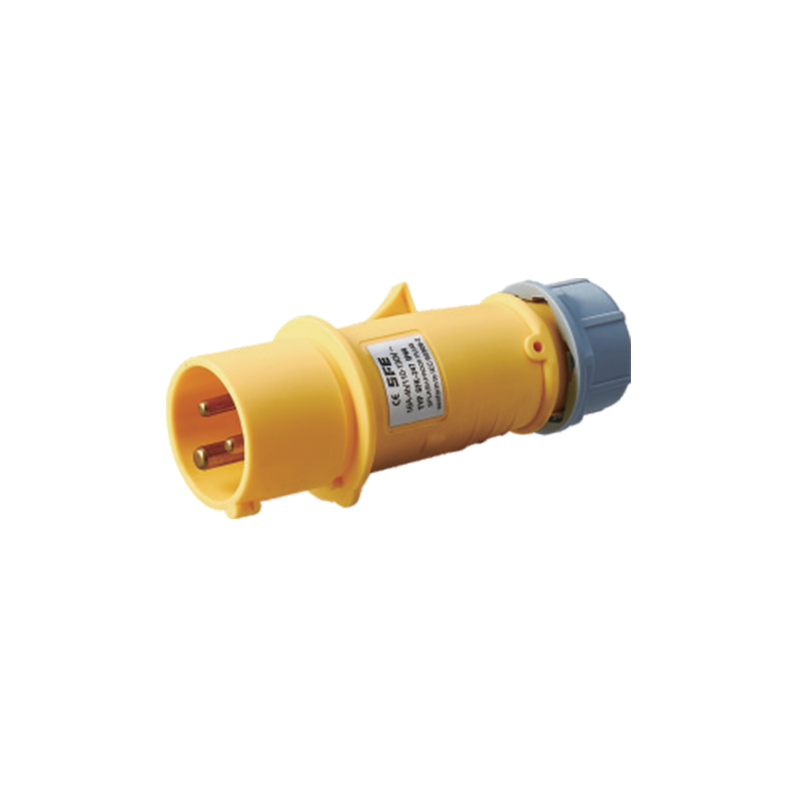

Industrial Connector play a crucial role in ensuring the efficiency and reliability of manufacturing processes. These components serve as the link between electrical systems, allowing seamless power transmission and signal communication across different machinery and equipment. Without high-quality industrial connectors, modern automation and production lines would face frequent disruptions, leading to delays and increased maintenance costs.

One of the key advantages of industrial connectors is their ability to withstand harsh working environments. Many manufacturing facilities expose equipment to extreme temperatures, vibrations, moisture, and dust. To ensure durability, manufacturers design industrial connectors with materials that resist corrosion and wear. This extends their lifespan and minimizes the risk of electrical failures.

Another important aspect is the adaptability of industrial connectors. With technological advancements, industries require connectors that support faster data transfer and higher power loads. Modular designs have become increasingly popular, allowing for easy customization based on specific industrial needs. Additionally, quick-connection mechanisms help reduce downtime during maintenance or upgrades.

As industries continue to automate and integrate smart technologies, industrial connectors will remain essential components in modern production. Their ability to maintain secure and stable connections ensures that machinery operates efficiently, contributing to improved productivity and cost savings in the long run.

https://www.socketsfe.com/product/

| Current(A): | 16A, 32A |

| Voltage(V): | 110-130V~2P+E |

| Protection degree: | IP44 |