The straight cutter tool continues to serve as a go-to solution for industries that demand linear precision in their cutting operations. With a simple yet effective design, this tool adapts well to repetitive processing environments such as panel trimming, joint preparation, and groove forming.

In large-scale production, consistent edge quality is necessary. Straight cutter tools are mounted in automated systems to ensure repeatable results. Woodshops and cabinetry factories depend on them to produce flush cuts on materials like plywood and MDF. Their geometry allows for faster passes and minimized surface tearing when matched with suitable spindle speeds.

In addition to wood processing, plastic fabricators often select straight cutters to work on thermoplastics. Whether the task is routing sign boards or trimming sheets for enclosures, this tool’s sharp edge and straightforward path contribute to smooth finishes without excessive sanding.

Precision is equally important in aluminum fabrication. While straight cutter tools are generally reserved for light to moderate tasks in metalworking, they can be utilized effectively when adjusted for feed rate and depth control. Cooling and lubrication improve outcomes and preserve the cutting edge.

One of the advantages of the straight cutter tool lies in its easy maintenance and predictable wear pattern. With proper cleaning and sharpening, the cutter can maintain its performance over multiple cycles. Many workshops keep several cutters in rotation to manage downtime and maintain output quality.

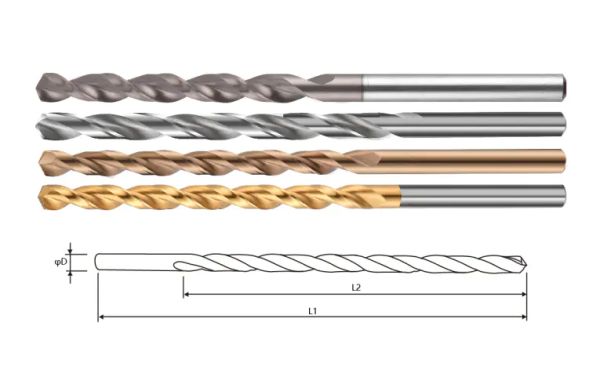

Design variations in straight cutter tools offer a degree of customization. Some come with fluted edges for faster chip clearance, while others have solid designs for extra rigidity. Choosing the right configuration depends on the application, material type, and machine setup.

In summary, the straight cutter tool remains a staple in many industrial applications due to its direct approach to cutting and its adaptability across different workflows. Its simplicity is its strength, offering clean lines and dependable results in structured processes.