What is a Safety Valves

Spring Loaded Safety Valves

safety valves is a valve mechanism which instantly releases a substance from a boiler, pressure vessel, or any other system, once the pressure or temperature exceeds preset limits.It is among a group of pressure safety valves (PSV) or pressure relief valves (PRV), that also includes relief valves, safety relief valves, pilot-operated relief valves, low pressure safety valves, and vacuum pressure safety valves.Safety valves were first utilized on steam boilers throughout the Industrial Revolution. Early boilers operating without one were vulnerable to accidental explosion.Vacuum safety valves (or combined pressure/vacuum safety valves) are utilized to prevent a tank from collapsing even though it is being emptied, or when cold rinse water can be used after hot CIP (clean-in-place) or SIP (sterilization-in-place) procedures.

Spring loaded safety valves is a valve designed to protect a pressurized vessel or system during an overpressure problem.

An overpressure problem can be consider any condition which would cause pressure in a vessel or pipeline to goes up beyond the pre set pressure or maximum allowable working pressure (MAWP).

The usage of a safety valve is protection of life and property by venting fluid from an overpressurized vessel.

Many electronic, pneumatic and hydraulic systems exist today to control fluid system variables, such as pressure, temperature and flow. Each of these systems requires a power source of some type, such as electricity or compressed air in order to operate. A pressure Relief Valve must be capable of operating at all times, especially during a period of power failure when system controls are nonfunctional.

When occurs that causes the pressure in a pipeline or vessel to goes up to a dangerous level, the pressure Relief Valve may be the only device remaining to prevent a catastrophic failure. Since reliability is directly related to the complexity of the device, it is important that the design of the safety valve be as simple as possible.

The safety valve has to open at a predetermined set pressure, flow a rated capacity at a specified overpressure, and shut down when the pipeline pressure has returned to a safe level. Safety valve must be designed with materials suitable with many process fluids from simple air and water to the most corrosive media. They must also be designed to operate in a consistently smooth and stable manner on a variety of fluids and fluid phases.

Spring Loaded Safety valves

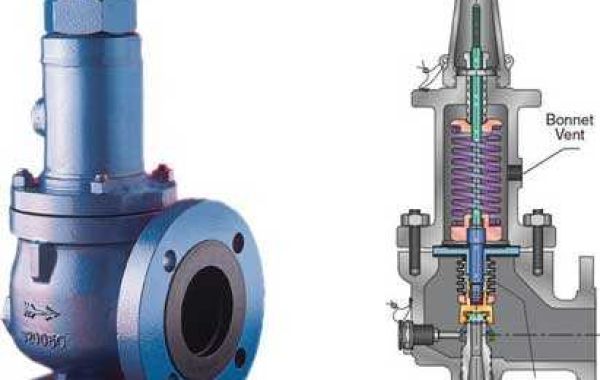

The basic spring loaded safety valve has been developed to suit the need for a simple, reliable, system actuated device to provide overpressure protection.

The Valve consists of a Valve inlet or nozzle mounted on the pressurized system, a disc held against the nozzle to prevent flow under normal system operating conditions, a spring to hold the disc closed, and a body/Bonnet to contain the operating elements. The spring load is adjustable to vary the pressure at which the Valve will open.

When a safety valve begins to lift, the spring force increases. Thus system pressure must increase if lift is to continue. For this reason pressure Relief Valves are allowed an overpressure allowance to reach full lift. This allowable overpressure is generally 10% for Valves on unfired systems. This margin is relatively small and some means must be provided to assist in the lift effort.

Most pressure Relief Valves, therefore, have a secondary control chamber or huddling chamber to enhance lift. As the disc begins to lift, fluid enters the control chamber exposing a larger area of the disc to system pressure.

This causes an incremental change in force which overcompensates for the increase in spring force and causes the Valve to open at a rapid rate. At the same time, the direction of the fluid flow is reversed and the momentum effect resulting from the change in flow direction further enhances lift. These effects combine to allow the Valve to achieve maximum lift and maximum flow within the allowable overpressure limits. Because of the larger disc area exposed to system pressure after the Valve achieves lift, the Valve will not close until system pressure has been reduced to some level below the set pressure. The design of the control chamber determines where the closing point will occur.

The difference between the set pressure and the closing point pressure is called blowdown and is usually expressed as a percentage of set pressure.

Balanced Bellows Valves and Balanced Piston Valves

When superimposed back pressure is variable, a balanced bellows or balanced piston design is recommended. A typical balanced bellow is shown on the right. The bellows or piston is designed with an effective pressure area equal to the seat area of the disc. The Bonnet is vented to ensure that the pressure area of the bellows or piston will always be exposed to atmospheric pressure and to provide a telltale sign should the bellows or piston begin to leak. Variations in back pressure, therefore, will have no effect on set pressure. Back pressure may, however, affect flow.

Pressure Relief Valve Bellow Type

Codes, Standards and recommended Practices

Many Codes and Standards are published throughout the world which address the design and application of pressure Relief Valves. The most widely used and recognized of these is the ASME Boiler and Pressure Vessel Code, commonly called the ASME Code.

Most Codes and Standards are voluntary, which means that they are available for use by manufacturers and users and may be written into purchasing and construction specifications. The ASME Code is unique in the United States and Canada, having been adopted by the majority of state and provincial legislatures and mandated by law.

The ASME Code provides rules for the design and construction of pressure vessels. Various sections of the Code cover fired vessels, nuclear vessels, unfired vessels and additional subjects, such as welding and nondestructive examination. Vessels manufactured in accordance with the ASME Code are required to have overpressure protection. The type and design of allowable overpressure protection devices is spelled out in detail in the Code.