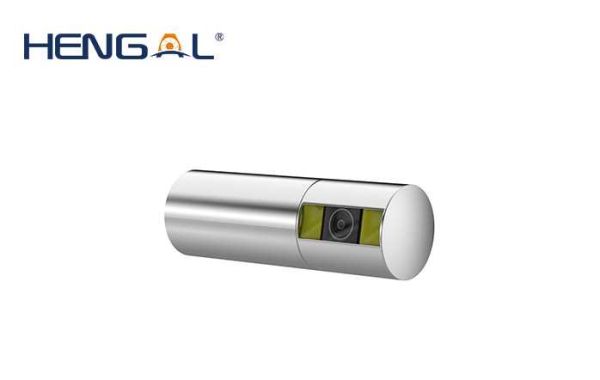

4.5mm medical endoscope camera module 4.5mm is a product of non-destructive testing in instrumentation and a specialized testing technology. Due to the special size design of the 4.5mm medical endoscope camera module 4.5mm, the inner surface structure or working state of the object can be observed simply and accurately without destroying the surface of the object.

Industrial endoscopes can be used to study the inspection and observation of high temperature, toxic, nuclear radiation and places that cannot be directly observed by the human eye, mainly including Chinese automobiles, airline engines, pipelines, mechanical design parts, etc., can realize non-destructive testing without disassembling or destroying the assembly and the equipment does not stop working. On the other hand, industrial endoscopes can also be combined with cameras, Cameras or e-commerce computer network connections form a photography, videography and image processing information system, which affects the monitoring, recording, storage and image analysis of effective field of view targets. It provides a good guarantee for diagnosis and treatment. The application and research time of endoscope in the construction engineering industry is relatively short, but its use and teaching effect is relatively excellent. Inspection of holes, walls, door and window joints and water pipes that are difficult to visually inspect. Installation and inspection of central air-conditioning, TV and network cables, combined with borescope.

4.5mm medical endoscope camera module 4.5mm leads the new trend of wind turbine gearbox inspection. When the industrial endoscope detects the wind power gearbox, the probe can be partially inserted into the wind power gearbox by using the gap of the wind power gearbox, and the wind power gearbox and internal management can be checked on the display screen of the host system. In addition, the detection effect of the present invention is intuitive, which is more intuitive than other methods, greatly improves work efficiency, and can detect areas in the gearbox that cannot be directly seen by human eyes without disassembling the equipment, which is very convenient. Product development has a megapixel high-brightness fiber optic lighting system design, 360-degree electric vehicle steering, zero-delay lock orientation, replaceable lenses, and a variety of basic styles to meet the requirements of various working conditions of enterprises and solve problems. Various gearboxes testing technical requirements. When testing the wind gearbox, you can control the probe to rotate 360° by operating the remote control rod of the industrial endoscope to observe the internal conditions of the wind gearbox in all directions. With the help of the display screen, the inspector can see the wear, tooth surface gluing and cracks of its components. Maintenance personnel can formulate maintenance plans for the faults or hidden dangers of the wind turbine gearbox as soon as possible to solve the fault of the wind turbine gearbox and ensure the normal operation of the wind turbine.

Although the industrial endoscope is not widely used in study and life, it is widely used in China's industrial development and can be detected without unpacking It is easy to analyze the faults of the machine for various problems of the machine. We should follow scientific use procedures in the process of use, so as to avoid damage to the machine and shorten the service life of the machine. It is necessary to understand the development characteristics of the internal control structure of the inspection workpiece, the specific research content and location of the inspection problem, and analyze the relevant linked instruments according to the procedure, check whether the power supply and grounding are reliable, and the instrument location information is safe and stable.

4.5mm medical endoscope camera module 4.5mm https://www.hengal-tech.com/4-5mm-medical-endoscope-camera-module-4-5mm-pshow/17.html