The quality of asphalt raw materials and mixture quality in strict accordance with the requirements of "Highway asphalt pavement construction Technical Specifications" (JTG F40 -- 2004) for selection, mixing and construction. Try to use high quality asphalt from professional technology with high deformation capacity at low temperature.

(2) Control the construction quality of the semi-rigid base, conditional can use asphalt gravel flexible base, in order to alleviate the degree of mesh cracking or cracking.

(3) Before asphalt pavement paving, the underlying layer should be carefully checked, the putty should be removed in time, the weak layer should be dealt with, the stability of the underlying layer should be ensured, and the sticky layer asphalt should be sprayed.

(4) Each layer of asphalt surface should meet the minimum construction thickness requirements, to ensure a good connection up and down; Measures are taken from design, construction and maintenance to effectively remove the water in the structure layer after rain.

The pavement structure design should do a good job of traffic volume investigation and prediction work, so that the pavement structure combination and overall strength to meet the design period of traffic load requirements. On the base must choose a good water stability of coarse grain of lime, cement stable materials.

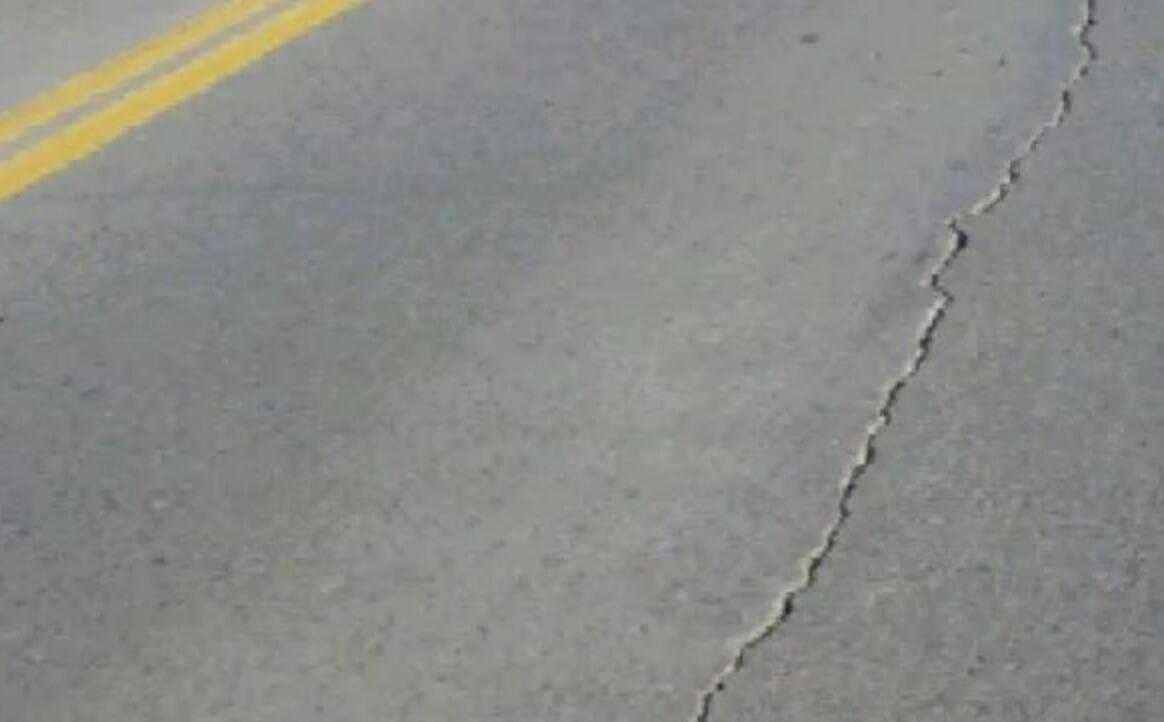

Prevention and control of reflection cracks

Take effective measures to reduce the shrinkage crack of semi-rigid base.

The base mixture should be close to the best water content in the state of rolling, to prevent rolling water content is too small, compactness and strength is insufficient, resulting in strength cracks.

For the base of subsection construction, when rolling, 3-5m mixture should be reserved for temporary rolling, and the next section of mixture should be rolled together after spreading, so as to facilitate connection. For the layered rolling base, the upper and lower joints should be staggered by 3-5m to reduce the chance of cracks.

Reasonable choice of mixture ratio, control the number of fine material; Pay attention to the maintenance of the structure layer, and lay the upper or lower sealing layer as soon as possible to reduce dry shrinkage joints.

Before the old road cover asphalt pavement structure layer, milling the original road surface and then add the cover, or the laying of geotextile, geogrid and then add the cover, to delay the formation of reflection cracks.

There are another materical-concrete can be used for road construction, please check out models of self truck to learn how to production concrete by self loading concrete mixer.