stages of concrete production

Concrete, or what is known as cement, goes through several stages from the extraction of raw materials to packaging, and the stages are graded as follows

Mining

The raw materials used in the concrete industry are extracted, which consists mainly of specific types of clay, such as saffron clay, kaolin, alluvial clay, as well as limestone, and these materials are loaded in trucks and transported to special silos for crushing limestone, and special silos for crushing clay.

Raw material reclamation

The limestone is first placed in the first crusher called jaw until it is crushed, then it is passed to the second crusher, and mixed with clay at the rate of seventy percent of limestone, and thirty percent of clay, then the mixture is recovered through a process called recovery in the crusher, and other materials are added to it It is pure limestone that is crushed alone in a jaw crusher, iron ore, and sand, and all these ingredients are mixed in a place called the lime box; to be crushed together.

Drying, mixing, homogenizing

This stage, as the title indicates, is divided into three sections, which are first drying the mixture in mills called pneumatic mills divided into two chambers, namely the drying room, and the grinding chamber, in which the size of the granules must be from thirty to ninety millimeters, then these materials pass through a device that separates the materials After the previous stage comes the stage of separating the mixture through special silos into fine materials and gases, for processing to the next stage, which is known as the thermal conversion process

clinker

In this step, the concrete mixture passes through five stages, which are the combustion chamber, then the riser duct, then the rotary kiln that is heated by hot gas, then the cooled grater, then the cement balls formed are taken out and ground in the next stage.

Cement grinding and storage

Materials are extracted from the mixture formed in the previous stage, such as gypsum, limestone, and other materials, and shipped to cement mills until they are ground and have a smooth texture.

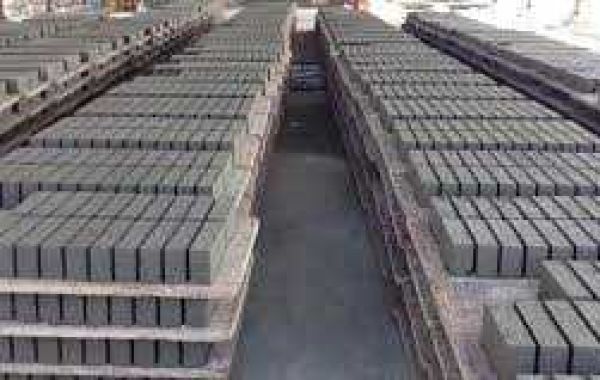

packing

This is the last process in the concrete manufacturing stage; The cement is packed in bags that carry a weight of fifty kilograms, and sent by trucks to its designated destinations.

TRANSLATED FROM: