Die castings made of zinc alloy have already made their way into virtually every aspect of modern life, including electronic cigarettes, knobs, model cars, bluetooth speakers, and a wide variety of other products. Zinc alloy die castings are also used in a number of other applications. When it comes to surface treatment, the requirements are typically quite stringent, and functions such as wear resistance and corrosion resistance are all required components. Surfaces must also be able to withstand chemical corrosion. The ability of surfaces to resist chemical corrosion is another requirement. Additionally, there is a low tolerance for surface flaws on aluminum die casting parts the product, such as blistering, which could be considered a defect. This is because there is a high standard for quality control. Because of this, the majority of the problems manifest themselves within the castings themselves, rather than simply in the castings' external presentation.

1. It could be found while the item is being sharpened or polished, which is a common time for such discoveries. The vast majority of the holes that have been discovered up to this point have been discovered on the inside of the object, and these holes will not become apparent until the processing has been completed. When the gas in the cavity, the gas volatilized by the paint, and the gas precipitated by the solidification of the alloy are not adequately exhausted in the mold, they will eventually remain in the pores that are formed in the casting. This occurs for three different reasons: the gas in the cavity, the gas volatilized by the paint, and the gas precipitated by the solidification of the alloy. This may occur if the mold does not receive an adequate supply of ventilation. As a result of the process of filling the mold with liquid metal and allowing it to solidify, holes are formed not only on the surface of the casting but also on the interior of the mold where the casting was made. The penetration of gas led zinc die casting to the formation of these holes. If these gases are not exhausted from the casting in an adequate manner, holes will form not only on the surface of the casting but also on the interior of the casting.

During the process of solidification of molten metal, the formation of a shrinkage cavity can be caused by either the volume shrinking or the molten metal being unable to feed the final solidified part. Both of these scenarios can result in the formation of a cavity.a. Castings with uneven thickness or local overheating of castings will cause a certain part to solidify slowly, and when the volume shrinks, the surface will form a concave position. b. Castings with uneven thickness or local overheating of castings will cause a certain part to solidify slowly.Castings that have an uneven thickness or castings that have been locally overheated will cause a particular part to solidify more slowly.Baking is the step that follows painting and electroplating in the production process.When the holes are heated, either the gas that is contained within the holes will expand, causing the volume to increase, or the water that is contained within the holes will turn into steam, causing the volume to increase. However, only one of these two possibilities will occur when the holes are heated.

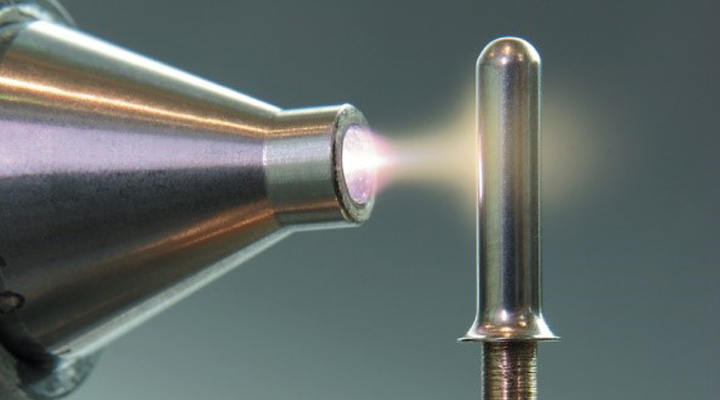

Electroplating is a process that helps to speed up the progression of intergranular corrosion, a disease that leads to the destruction of the metal matrix.Intergranular Plating corrosion has the potential to deform, crack, and even break castings when it is present in humid environments. This corrosion can even cause castings to break.

Die castings made of zinc alloy have already made their way into virtually every aspect of modern life, including electronic cigarettes, knobs, model cars, bluetooth speakers, and a wide variety of other products. Zinc alloy die castings are also used in a number of other applications. When it comes to surface treatment, the requirements are typically quite stringent, and functions such as wear resistance and corrosion resistance are all required components. Surfaces must also be able to withstand chemical corrosion. The ability of surfaces to resist chemical corrosion is another requirement. Additionally, there is a low tolerance for surface flaws on the product, such as blistering, which could be considered a defect. This is because there is a high standard for quality control. Because of this, the majority of the problems manifest themselves within the castings themselves, rather than simply in the castings' external presentation.

1. It could be found while the item is being sharpened or polished, which is a common time for such discoveries. The vast majority of the holes that have been discovered up to this point have been discovered on the inside of the object, and these holes will not become apparent until the processing has been completed. When the gas in the cavity, the gas volatilized by the paint, and the gas precipitated by the solidification of the alloy are not adequately exhausted in the mold, they will eventually remain in the pores that are formed in the casting. This occurs for three different reasons: the gas in the cavity, the gas volatilized by the paint, and the gas precipitated by the solidification of the alloy. This may occur if the mold does not receive an adequate supply of ventilation. As a result of the process of filling the mold with liquid metal and allowing it to solidify, holes are formed not only on the surface of the casting but also on the interior of the mold where the casting was made. The penetration of gas led to the formation of these holes. If these gases are not exhausted from the casting in an adequate manner, holes will form not only on the surface of the casting but also on the interior of the casting.

During the process of solidification of molten metal, the formation of a shrinkage cavity can be caused by either the volume shrinking or the molten metal being unable to feed the final solidified part. Both of these scenarios can result in the formation of a cavity.a. Castings with uneven thickness or local overheating of castings will cause a certain part to solidify slowly, and when the volume shrinks, the surface will form a concave position. b. Castings with uneven thickness or local overheating of castings will cause a certain part to solidify slowly.Castings that have an uneven thickness or castings that have been locally overheated will cause a particular part to solidify more slowly.Baking is the step that follows painting and electroplating in the production process.When the holes are heated, either the gas that is contained within the holes will expand, causing the volume to increase, or the water that is contained within the holes will turn into steam, causing the volume to increase. However, only one of these two possibilities will occur when the holes are heated.

Electroplating is a process that helps to speed up the progression of intergranular corrosion, a disease that leads to the destruction of the metal matrix.Intergranular corrosion has the potential to deform, crack, and even break castings when it is present in humid environments. This corrosion can even cause castings to break.

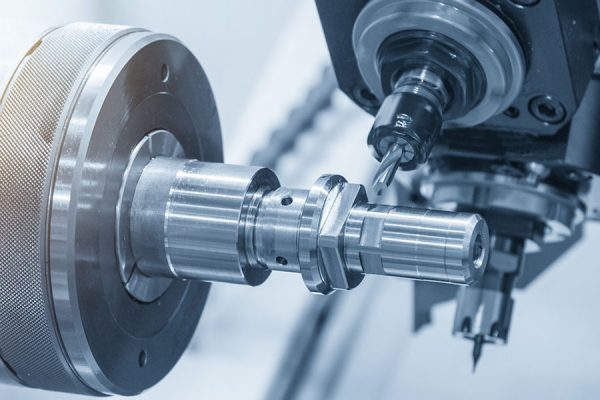

To summarize, the blistering phenomenon of zinc alloy plating is a phenomenon that frequently occurs during the electroplating process. This phenomenon can be seen as a result of zinc alloy plating. Even if a particular electroplater only processes zinc alloy plating very infrequently or not at CNC machining all, they are still required by the electroplating manufacturer to go through the inspection process.

3. Water streaks on the surface of the casting are typically not very deep. On the other hand, cold seals can occasionally make their way into the interior of the casting. Whenever there are water marks, cold barrier marks, or hot cracks present in the die-casting, the solution will seep into the cracks in the die-casting while the electroplating process is in progress. During the baking process, the solution will turn into steam as a byproduct of the evaporation process. Additionally, the air pressure will cause the electroplating layer to be forced upward, which will lead to the formation of bubbles. After conducting research on a simulation of the process of die-casting, which is a process in which liquid metal is poured into the cavity from the casting system, it has become abundantly clear that the sharp transition position and the incremental pouring in the runner are two essential steps in the process. Additionally, it has become abundantly clear that the sharp transition position and the incremental pouring in the runner are two essential steps in the process. The runner's cross-sectional area will cause the flow of the molten metal China die casting manufacturer to become turbulent, which will cause gas to become entrained in the flow. Additionally, the stable flow of the molten metal will make it more likely for gas to enter the overflow groove and exhaust groove from the runner and the cavity, and then be discharged from the mold. This is because the turbulent flow of the molten metal will cause gas to become entrained in the flow.

By giving careful consideration to the design of the nozzle, the thickness and position of the ingate, the design of the mold, the regulation of the temperature, and the cooling of the mold, it is possible to prevent the formation of shrinkage cavities. This can be accomplished. By increasing the temperature of the mold to a higher setting, increasing the speed of the ingate, or widening the overflow groove in the region of the cold barrier, it is possible to reduce the visibility of water marks and cold barrier marks. Within the area that is encompassed by the cold barrier, any or all of these modifications could be implemented. In order to reduce the amount of stress that is caused by the die-casting process, you should avoid making sudden changes in the thickness of the parts. When something is being manufactured, the two processes that typically come immediately before the electroplating step are called degreasing and pickling. The pickling solution is typically a mixture of three distinct acids, whereas the degreasing solution is typically an alkaline degreaser that is able to function at room temperature. This is as a result of the fact that degreasing typically consists of the component being soaked and stirred with a heated degreaser at room temperature for a considerable amount of time. Because of this, the amount of time required for the chemical reaction to take place is lengthened as a result. Because of this, zinc alloys almost never require degreasing prior to electroplating, and electroplating can take place even after the material has been activated with sulfuric acid. As a result of this, electroplating is one of the few processes that can be performed on zinc alloys. This malfunction may take place if the zinc alloy die-casting is subjected to temperatures that are too high.