Fiber Reinforced Sheet Molding Compound (SMC) is a remarkable material known for its strength and versatility, and the molds used to shape it play a crucial role in various industries. Among the many applications of SMC, the creation of durable and reliable shells stands out as a testament to the power of precision engineering.

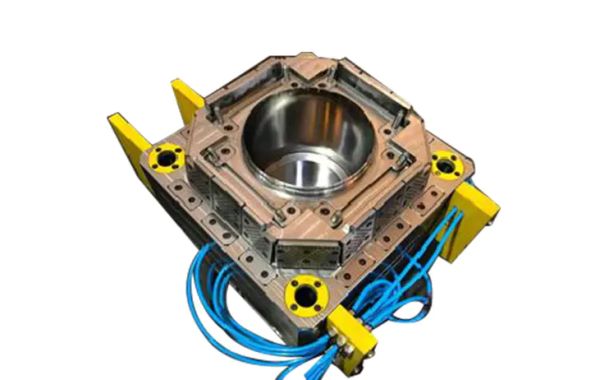

Fiber Reinforced SMC Shell Molds are engineered with precision to create strong and resilient shell structures. These molds play a pivotal role in industries like automotive manufacturing, where the need for lightweight yet durable components is paramount. From car body panels to utility enclosures, the versatility of SMC ensures it can meet a wide range of needs.

One of the key advantages of SMC shell molds is their ability to produce complex shapes and intricate designs with ease. This makes them ideal for crafting aesthetically pleasing and functional parts that meet strict safety and performance standards.

Furthermore, the durability of Fiber Reinforced SMC Shell Molds ensures a long service life, which is crucial for maintaining consistent quality in mass production settings. These molds can withstand the high pressures and temperatures required to form SMC, making them an indispensable tool for industries that demand precision and durability.

In conclusion, Fiber Reinforced SMC Shell Molds are at the heart of crafting strong and durable shell structures across various industries. Their precision engineering and ability to create complex shapes contribute to the production of high-quality, long-lasting components.