If you're in an area using a substantial variety of coconut shells, you could consider purchasing a biomass pyrolysis plant. They are unique machines that come in an array of sizes and used throughout the globe to process materials like rubber, plastic, and other inorganic materials to create biofuel and bio-oil. They could ideally be utilized for organic materials like coconut shells to help make high-quality charcoal.

The coconut shell charcoal making machine is now probably the most loved machinery by vigilant entrepreneurs. It may help you will be making additional revenue after some time. As a matter of fact, there are numerous benefits to buying this machinery. However, it makes sense when you invest in a quality one and this is where reputable charcoal making machine manufacturer or supplier is important. There are various aspects to be aware of when selecting the correct machinery supplier. With that being said, here are among the most critical elements to bear in mind:

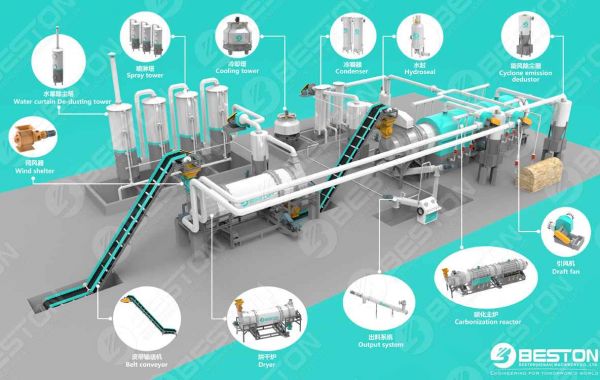

Most coconut shell charcoal briquettes making machine utilize an oxygen-free carbonization tech utilizing high temperature as a means to transform coconut shells into charcoal and also biogas. High quality machinery can process coconut shells along with other waste elements like sewage sludge, palm kernel shell, wood, peanut shells, green waste, agriculture, bamboo, sawdust, municipal solid waste, and rice husks. Coconut charcoal has a huge demand, specifically in the BBQ sector. That's because it has high thermal energy, it's clean and non-toxic. So, in case you are in a place with numerous coconut shells every day, you ought to purchase this machinery without further delay.

Coconut shell charcoal machinery can be purchased in 2 types the bath coconut shell charcoal making system as well as the continuous coconut shell charcoal machinery. The charcoal is just discharged right after the machine has been cooled and another batch begins right after the previous one is fully discharged. From the continuous type, charcoal is manufactured within a continuous manner. It discharges this product even though the raw material is now being fed with the machinery's feeding system. You'll wish to pick the best one based on your needs and budget. As for the manufacturer or supplier, you will find few facts to consider.

You should be sure you invest your hard earned money inside a top of the line machine, made by a respected manufacturer or supplied by a trusted supplier. So, you'll want to find just how long the supplier has been doing the industry. The longer the more effective because it shows they are doing something right. This equipment is not cheap at all therefore, the last thing you would like is to skimp from the supplier selection process.

The net is a good place to begin your quest. Reviews on Google and social websites platforms and also forums can tell you whether to deal with a certain supplier or otherwise. Remember to check out the way that they cope with complaints as well as the competency of the customer support. You'll want a piece of equipment that may be quickly attended to once you have an issue and it also all starts by choosing the right manufacturer or supplier.