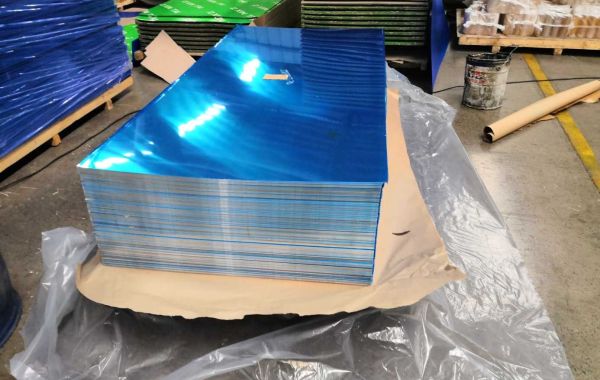

An anodized aluminum sheet is received by way of having the floor of the alu sheet anodized to get an anodizing film. This film, tough and corrosion resistant, enables to increase the carrier lifestyles of the sheet greatly. To choose the satisfactory of anodized aluminium sheets, you ought to awareness on the subsequent four elements.

Logo inspection: every anodized aluminium sheet we typically sees is categorized, and the brand has the usual code and license of the product.

The thickness of the oxide film: This requires the use of a professional eddy current thickness measuring instrument for trying out.

Floor nice inspection: in addition to cleaning the floor of the anodized aluminum plates, we want to peer extra matters. For instance, we have to test whether or not the aluminum plate has a few cracks or a few corrosion. Those are all It requires cautious commentary to discover.

Sealing excellent acid leaching approach: The formation of the sealing is fashioned after the anodic oxidation. If those sealings aren't properly handled, it's going to cause the subsequent corrosion of the aluminum plate. Normally the detection approach we carry out is the acid leaching technique, this is, after disposing of the dust on the floor, drop nitric acid at the floor, wipe it lightly, wash off the nitric acid with water, and then drop red syrup at the floor, and wipe it off after one minute. See if there are any obvious lines on the floor. If there are, it manner that the sealing isn't accomplished properly.

When you have greater questions on anodized aluminium sheet fine, welcome to touch us!

Recherche

Messages populaires