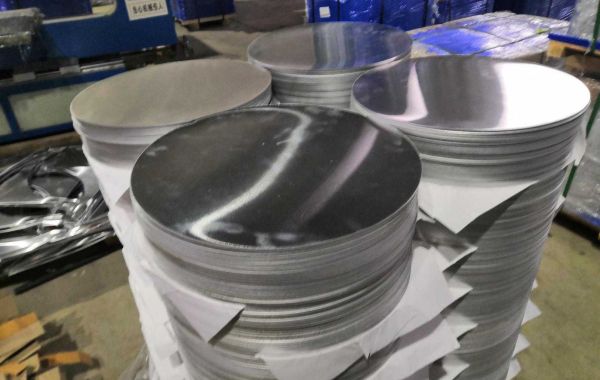

The 1060 aluminum circle plate is used for items requiring high corrosion resistance and forming ability. Its strength is not high, and chemical equipment is its typical use. Aluminium circle 1060 can be cold extruded into capacitor housings, hoses and aluminum housings in a variety of sizes. Aluminum wafers are widely used in electronics, daily chemicals, pharmaceuticals, culture and education, and automotive parts.

1060 aluminum circle plate, containing more than 99.6% aluminum, is a commonly used series in the aluminum strip family. The upper hand of this series of aluminum plates: the most commonly used series, the production process is relatively simple, the technology is relatively mature, and the price has a huge advantage compared with other high-grade alloy aluminum plates. With good elongation and tensile strength, it is fully capable of meeting the normal processing requirements (stamping, drawing) and high formability. Pure aluminum for industry, with high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but low strength, heat treatment can not enhance the machinability; gas welding, hydrogen atom welding and contact welding, not easy to braze; easy to withstand Pressure processing and extension, bending.

The aluminum pan we usually use can be made of 1060 aluminium circle plate. It has a thin oxide film on the surface, only 0.00001 mm thick. In the industry, in order to make the aluminum wafer more durable, it will often The produced 1060 aluminum wafer is processed to make the oxide film thicker, so that the aluminum pan is not afraid of acid or alkali. Aluminum wafers do not rust for a long time, but only chemical reactions occur to form alumina.

Recherche

Messages populaires