Well intervention and workover operations play a crucial role in maintaining the productivity and integrity of oil and gas wells throughout their lifecycle. These operations involve a variety of complex tasks, including remedial actions, equipment installations, and reservoir management techniques. Simulation-based training programs have emerged as essential tools for preparing personnel to execute well interventions and workovers effectively. In this article, we delve into the role of simulation-based training in these operations, exploring how simulations replicate downhole conditions and challenges to allow personnel to practice intervention techniques and optimize well performance.

Understanding Well Intervention and Workover Operations

Well intervention refers to any operation carried out on an oil or gas well to alter its state or performance, while workover operations involve the remediation or enhancement of well integrity and productivity. These operations may include tasks such as perforation, stimulation, logging, hydraulic fracturing, and equipment retrieval/installation, among others. Well intervention and workover activities are essential for maximizing hydrocarbon recovery, mitigating production declines, and addressing reservoir challenges throughout the well's lifespan.

Challenges in Well Intervention and Workover Operations

Well intervention and workover operations present numerous challenges for personnel, including:

- Downhole Complexity: Wells can exhibit complex downhole conditions, including variations in pressure, temperature, fluid composition, and reservoir characteristics, which require careful planning and execution of intervention techniques.

- Technical Complexity: Performing interventions and workovers often involves the use of specialized equipment and tools, as well as knowledge of wellbore dynamics, fluid mechanics, and reservoir engineering principles.

- Operational Risks: Well intervention and workover activities pose inherent risks to personnel safety, equipment integrity, and environmental stewardship, necessitating comprehensive risk assessment and mitigation strategies.

- Cost Considerations: Well interventions and workovers can be costly and time-consuming endeavors, requiring significant investments in equipment, personnel, and logistical support.

Simulation-Based Training for Well Intervention and Workovers

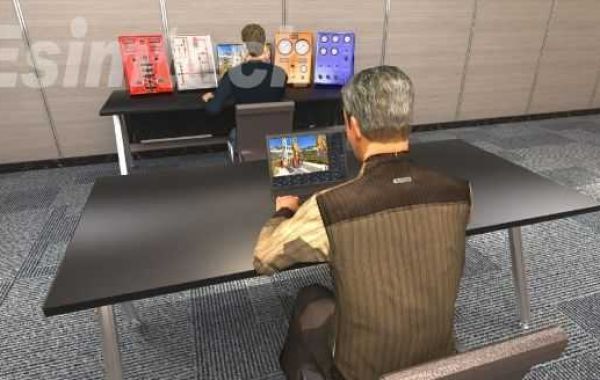

Simulation-based training programs offer a solution to address the challenges of well intervention and workover operations by providing realistic and interactive virtual environments for personnel to practice various intervention techniques and scenarios. Here's how simulations replicate downhole conditions and challenges to enhance training effectiveness:

- Realistic Downhole Environments: Simulations replicate downhole conditions, including wellbore geometry, reservoir properties, fluid behavior, and mechanical interactions, allowing trainees to experience realistic scenarios encountered during interventions and workovers.

- Equipment and Tool Replication: Simulators simulate the operation of downhole equipment and tools used in interventions and workovers, such as coiled tubing units, wireline tools, packers, and downhole sensors. Trainees can interact with virtual equipment, practice operating controls, and perform tasks as they would in real-world situations.

- Scenario-Based Training: Simulation-based training programs present trainees with a variety of intervention scenarios, ranging from routine maintenance tasks to complex remediation operations. Trainees are challenged to apply their knowledge and skills to solve problems, make decisions, and achieve operational objectives in a simulated environment.

- Risk-Free Practice: Simulation training allows personnel to practice intervention techniques and procedures in a safe and controlled environment, without the risk of damaging equipment or causing harm to themselves or others. Trainees can make mistakes, learn from them, and refine their skills without real-world consequences.

- Performance Evaluation and Feedback: Simulators provide real-time performance monitoring and assessment, allowing instructors to evaluate trainee proficiency, provide feedback, and identify areas for improvement. This feedback loop enables continuous learning and skill development throughout the training process.

Conclusion

Simulation-based training programs are invaluable tools for preparing personnel to execute well intervention and workover operations safely, efficiently, and effectively. By replicating downhole conditions and challenges in a realistic virtual environment, simulations enable trainees to practice intervention techniques, optimize well performance, and mitigate operational risks. As the oil and gas industry continues to evolve, simulation-based training will remain a cornerstone of personnel development and operational excellence in well intervention and workover operations.