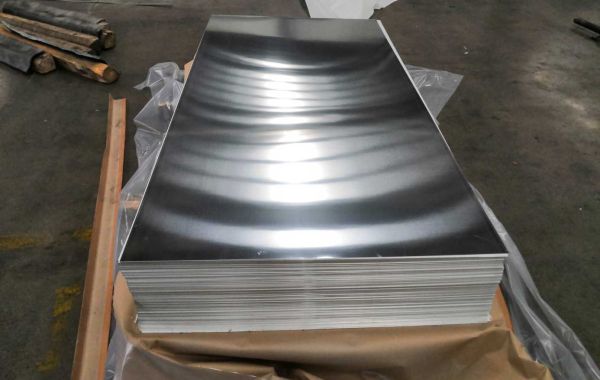

PVDF fluorocarbon coatings for prepainted aluminum 3003 are the darling of the present architectural coatings marketplace. And may be said to be recognized as natural coatings with extremely protective effects. Aluminum-magnesium-manganese 3003 aluminum is an alloy fabric composed of three factors of aluminum-magnesium-manganese. It has the blessings of excessive energy, properly toughness, corrosion resistance and aging resistance. Its structural electricity is moderate, weather resistant, stain resistant, smooth to bend and welded, and many others. Exceptional price performance, it's far taken into consideration to be a roof and outdoors wall material with a service life of extra than 50 years.

The 3003 aluminum sheet plate coil with fluorocarbon coating cloth utilized in metal construction can preserve it undamaged for decades and always keep lovely colors. So far, fluorocarbon prepainted aluminum-magnesium-manganese panels have been used in buildings in numerous fields round the arena for greater than 30 years, and that they have maintained their great performance. Colour coated aluminum sheet 3003 normally has a thickness of zero.024mm-4.0mm and a width of 1700mm or much less. Except of PVDF coating, there's also PE coating, which is low fee and can be used for indoors decoration. The coloration of prepainted aluminum can be study, green, blue, yellow, white, black and so forth. PVDF is polyvinylidene fluoride. Because of the electronegative homes of fluorine atoms, it bureaucracy a very strong fluorocarbon bond. Coupled with its unique molecular symmetry, PVDF has tremendous stability and unique resistance to ultraviolet light degradation. In addition to top notch insulation and mechanical residences. Because the application of fluorocarbon-lined aluminum-magnesium-manganese sheet, the pretreatment of aluminum-magnesium-manganese plates has regularly evolved within the direction of simplicity and high performance.

Before the anti-corrosion production of the aluminum-magnesium-manganese prepainted aluminum sheet coil, some more low-budget and sensible pretreatment measures ought to be taken for later use. So a way to save you corrosion of aluminum-magnesium-manganese color covered sheet? Within the beyond, the maximum normally used pretreatment approach become to deal with the floor of the aluminum-magnesium-manganese lined coil with an acid or alkaline approach to dissolve the oxide layer, rust and oil stains at the floor, after which carry out the subsequent step of anti-corrosion remedy.

Search

populaire posts

-

How To Love Yourself As A Senior Bbw

Door Christopher Miller

How To Love Yourself As A Senior Bbw

Door Christopher Miller -

Jobs That Are Perfect for People Who Like to Work With Their Hands

Door Kevin Gardner

Jobs That Are Perfect for People Who Like to Work With Their Hands

Door Kevin Gardner -

Best canadian pharmaceuticals online

Door Rosa Smith

Best canadian pharmaceuticals online

Door Rosa Smith -

What is the greatest online casino in Canada?

What is the greatest online casino in Canada?

-

Mentioned previously in despatches

Door SEO Consultant

Mentioned previously in despatches

Door SEO Consultant