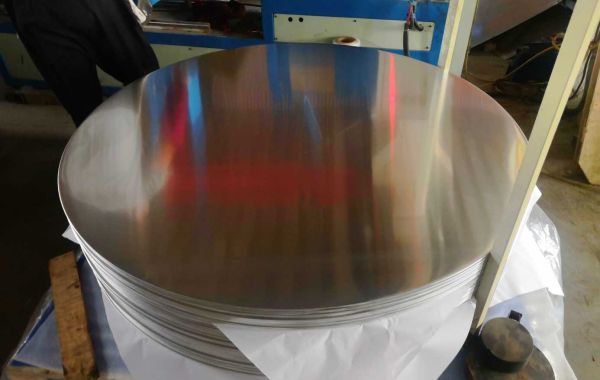

Each 1060 aluminum circle and 3003 aluminum circle are everyday participants of aluminium spherical circles. It’s tough to differentiate them by way of look, however there are variations virtually.

They first differ in mechanical contents and properties.

The 1060 aluminum circle is natural aluminum with an aluminum content material of ninety nine.6% or more and a density of almost 2.7, which is set one-third of that of iron. The melting point is 660.37 ° C, the boiling factor is 2750K. Typically used 1060-O state aluminum plate, 1060-H14 nation aluminum plate, 1060-H24 state aluminum plate, 1060-H18 nation aluminum plate. It's far particularly used for semi-tough aluminum plate for stamping hardware, thermal insulation aluminum for pipe insulation project, 1060-O aluminum spherical plate for mould deep drawing, and 5-ribbed plate for floor anti-skid.

The 3003 aluminum circle is an aluminum-manganese alloy which can not be bolstered via warmness remedy. The manganese content can boom the recrystallization temperature of the alloy. The heat treatment method is only annealing, and the annealing temperature is four hundred-six hundred °C. 3003 is an alloyed aluminum spherical plate with top corrosion resistance. Usually used states are divided into 3003-O state aluminum plate, 3003-H12 country aluminum plate, 3003-H22 state aluminium spherical circles, 3003-H14 nation aluminum plate, 3003-H24 state aluminum plate, 3003-H16 kingdom aluminum plate, 3003-H26 state aluminum plate, 3003-H18 Aluminum plate. It's miles mainly used for some products or engineering applications with high corrosion resistance necessities inclusive of pipeline insulation.

The second distinction is utility. Despite the fact that both are broadly utilized in electronics, every day chemical compounds, medicine, way of life and schooling, vehicle parts, thermal insulation, equipment manufacturing, automobile, aerospace, navy, mildew, production and printing etc. The application results are numerous. As an instance, kitchen utensils of 3003 aluminium circles are harder and lampshades of 3003 are extra corrosion resistant. However, in situations requiring little approximately hardness and corrosion resistance, the 1060 aluminum circle is a higher choice, for it costs less.

In a word, 3003 aluminum circle and 1060 aluminum circle range from every different in mechanical contents, houses and alertness. Clients have to select a suitable one according to their specific needs.

Suche

Beliebte Beiträge

-

How To Love Yourself As A Senior Bbw

Durch Christopher Miller

How To Love Yourself As A Senior Bbw

Durch Christopher Miller -

Jobs That Are Perfect for People Who Like to Work With Their Hands

Durch Kevin Gardner

Jobs That Are Perfect for People Who Like to Work With Their Hands

Durch Kevin Gardner -

Best canadian pharmaceuticals online

Durch Rosa Smith

Best canadian pharmaceuticals online

Durch Rosa Smith -

What is the greatest online casino in Canada?

What is the greatest online casino in Canada?

-

Mentioned previously in despatches

Durch SEO Consultant

Mentioned previously in despatches

Durch SEO Consultant

Kategorien