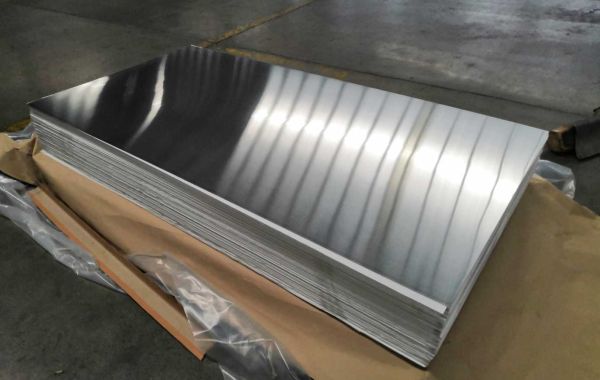

Both 5052 aluminum and 6061 aluminum alloys can go through the anodizing process to increase corrosion resistance and enable dying (coloring). The anodic layer is non-conductive.But 6061 aluminum sheet is the most usually used aluminum alloys. The principle alloy components are magnesium and silicon. Not unusual makes use of for this alloy are within the manufacturing of fishing reels, truck frames, structural additives, machine components, aircraft and aerospace additives, marine fittings, camera lenses, delivery, valves, and couplings.6061-T3 is not encouraged for sheet metallic paintings as it will crack at the out of doors radius as soon as it passes its yield when being processed on a brake press, for example.When in comparison with 6061 aluminum,Aluminum 5052 alloy is one of the better electricity, non-heat-treatable alloys, which includes magnesium as its major alloying detail, with small amounts of chromium, silicon, iron, copper, manganese and zinc. Whilst annealed, alloy 5052 is stronger than the comfortably available 1100 and 3003 alloys, and stronger than maximum other 5xxx collection alloys. 5052 alloy cannot be heat handled, but can be warm and cold labored.5052-H32 contains 2.5% magnesium. It's far one of the maximum strength alloys of the non-heat treatable grades. Common uses for this alloy include the manufacturing of electrical enclosures, marine components, home home equipment, meals device, gasoline tanks, hurricane shutters, fridges, plane tube, and fences.So 5052 aluminum is less expensive than 6061 aluminum,the aid is from professional aluminum producer-HUAWEI aluminum,we've got great satisfactory aluminum foil, circle, sheet, mirror and embossed sheet, coil and so on, so when you have any interested, experience loose to touch my e mail:sales@hw-alu.com

Cerca

Post popolari