The Efficiency Equation

Downhole efficiency is a delicate balance between several factors. We want to maximize the Rate of Penetration (ROP), the speed at which the drill bores through rock. But pushing the drill too hard can lead to equipment failure and costly downtime. The key lies in optimizing controllable drilling parameters like:

Weight on Bit (WOB): The force applied to the drill bit. Too little and drilling slows, too much and the bit can wear or break.

Rotations Per Minute (RPM): The speed at which the drill bit spins. Higher RPM can increase ROP, but also generate unwanted heat.

Mud Flow Rate: The rate at which drilling fluid circulates through the wellbore. This fluid cools the bit, removes cuttings, and maintains wellbore pressure. Finding the optimal flow rate is crucial.

Data Drives Decisions

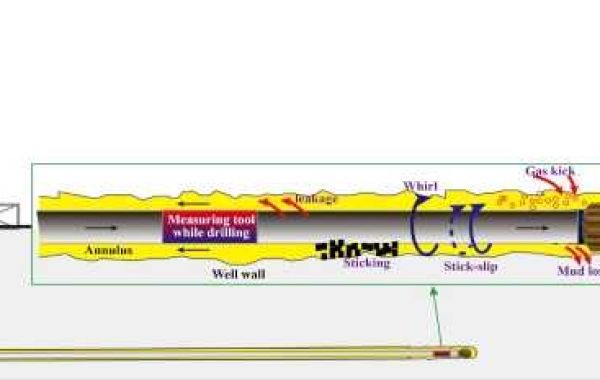

Traditionally, downhole optimization relied on experience and intuition. Today, data is king. Real-time downhole sensors monitor everything from vibration to pressure. This data feeds into sophisticated software that analyzes drilling parameters and recommends adjustments for optimal performance.

Beyond the Drill Bit

Efficiency isn't just about drilling faster. Wellbore planning plays a vital role.

Well Spacing Optimization: Strategically placing wells ensures maximum hydrocarbon recovery while minimizing drilling costs and environmental impact.

The Right Tools for the Job: Matching the drill bit type and drilling fluid properties to the specific geology can significantly improve ROP and overall wellbore health.

The Future of Downhole

The quest for downhole efficiency is a constant evolution. Machine learning algorithms are being developed to analyze vast datasets and predict optimal drilling parameters even in unforeseen conditions. Additionally, advancements in automation promise to streamline operations and minimize human error. The emergence of downhole operation simulation technology also provides new training directions for technical personnel, improving the safety and efficiency of real downhole operations

By embracing new technologies and data-driven approaches, the oil and gas industry can push the boundaries of downhole efficiency, extracting valuable resources responsibly and sustainably.