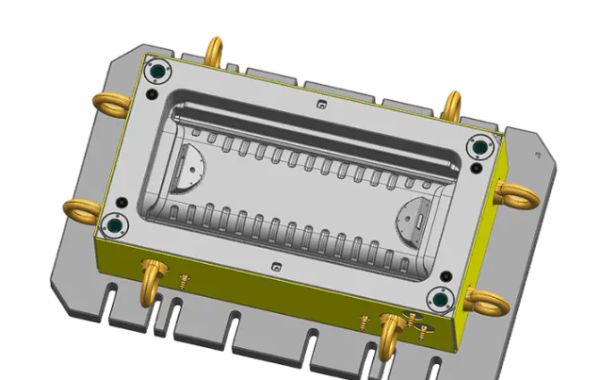

In modern automotive manufacturing, auto parts mold is essential for producing high-quality vehicle components that meet strict industry standards. This process involves creating precise molds that shape parts from various materials, such as metals and plastics, to achieve the desired specifications.

The process begins with designing a detailed model of the component, which is then used to create a mold. High-grade materials, such as hardened steel or aluminum alloys, are typically employed to construct these molds due to their durability and ability to withstand high temperatures and pressures. Techniques like injection molding, compression molding, and blow molding are commonly used to fill these molds with material, forming the final part.

Precision in mold design and manufacturing is critical, as it directly impacts the performance and safety of automotive parts. A well-crafted mold ensures that components are produced with uniformity and minimal defects, which is crucial for the vehicle’s overall functionality. For example, engine components and transmission parts must meet exact specifications to operate efficiently and reliably.

Advancements in technology have significantly improved mold-making processes. Computer-aided design (CAD) and advanced simulation tools help engineers refine mold designs and predict potential issues before production begins. This not only enhances the quality of auto parts but also reduces production costs and time.

Overall, auto parts mold is a cornerstone of modern automotive manufacturing, enabling the production of high-performance, reliable vehicle components. As technology progresses, the role of mold-making will continue to be vital in ensuring the advancement of the automotive industry.