While whipstock drilling offers several advantages, it also presents unique challenges that require careful planning and execution.

Common Challenges in Whipstock Drilling

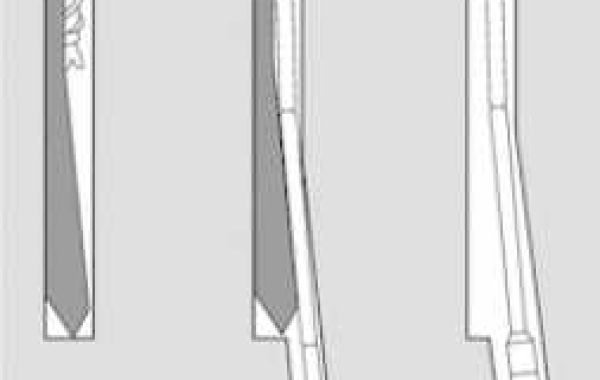

Whipstock Selection and Placement: Choosing the appropriate whipstock size and orientation is crucial for achieving the desired deviation angle. Incorrect selection or placement can lead to inadequate deflection or even failure.

Drill String Control: Maintaining control of the drill string during the deviation process is essential to prevent excessive bending and potential equipment damage. Factors such as drill string weight, rotary speed, and fluid flow rate must be carefully managed.

Formation Characteristics: The geological formations encountered during drilling can significantly impact the effectiveness of whipstock drilling. Hard, abrasive formations may increase wear on the whipstock and drill string, while soft, unconsolidated formations may present challenges in maintaining borehole stability.

Wellbore Stability: Deviating the wellbore can introduce additional stresses on the borehole wall, increasing the risk of collapse or other stability issues. Proper wellbore support and casing design are crucial to mitigate these risks.

Operational Efficiency: Whipstock drilling can be a time-consuming process, especially in complex geological formations. Optimizing drilling parameters and using advanced technologies can help improve efficiency and reduce costs.

Solutions to Overcome Whipstock Drilling Challenges

Proper drilling fluid selection: Choosing the right drilling fluid formulation can help to prevent stick-slip, formation collapse, and lost circulation.

Optimized drilling parameters: Carefully selecting drilling parameters, such as weight on bit and rotary speed, can help to minimize stick-slip and reduce the risk of bent whipstock.

Advanced drilling techniques: Techniques such as rotary steerable drilling (RSD) can be used to improve the accuracy and efficiency of whipstock drilling operations.

Wellbore strengthening: In challenging formations, wellbore strengthening techniques, such as casing and cementing, can help to prevent formation collapse and lost circulation.

Real-time monitoring: Using downhole tools to monitor drilling conditions in real-time can help to identify and address potential problems early on.

By understanding the common challenges associated with whipstock drilling and implementing effective solutions, operators can improve the success rate and efficiency of their drilling operations.