Galvanized steel is highly demanded in the building industry due to its peculiar resistance to corrosion. This paper examines how a zinc coating on steel prevents rusting, hence prolonging the life of construction materials with durability and dependability. The process of steel frame fabrication further enhances the structural integrity of buildings, making galvanized steel an even more attractive choice. Any member of the general public can, from owners of houses to construction experts, understand how this process is accomplished and why galvanized steel is advantageous over other types of steel for such purposes.

Understanding Galvanized Steel

Galvanized steel is a kind of steel coated by a layer of zinc to prevent corrosion. In the process, the steel is immersed in a bath of molten liquid zinc, whereby it creates a strong and protective layer. The zinc coating provides a protective shield against elements of nature, basically moisture and oxygen, which are critical triggers for rust formation.

This results in a material combining the strength of steel and the corrosion resistance of zinc; for this reason, galvanized steel finds such widespread applications as in construction, car parts, and household appliances.

How does a zinc coating prevent rust?

The zinc coating provides multi-level protection against rusting or the corrosion of steel. When applied to steel, zinc reacts with the environment to form an oxide that reacts with moisture to produce zinc hydroxide. This layer subsequently reacts over time with carbon dioxide in the air to produce a thin, but highly protective layer comprising zinc carbonate.

The layer formed is stable and very adherent to the steel surface, offering a reasonable barrier to rust.

Barrier Protection

The physical barrier caused by the zinc coating prevents the steel from coming into direct contact with the environment. The barrier prevents the occurrence of moisture and oxygen in contact with the underlying steel as they are assumed to be an important constituent that forms rust. Since the exposure of the elements is not experienced, the steels remain free from rust for quite an extended period even under harsh conditions. This is very true in coastal areas where salt water accelerates the corrosion process.

Cathodic Protection

One of the singular properties of zinc is sacrificial protection. Zinc is more active than steel; this means that it segregates before steel and corrodes first. The process is called cathodic protection. Where there is exposure to elements that cause corrosion, such as moisture and oxygen, the zinc layer will corrode preferentially to the steel.

Even when the zinc coating is scratched or damaged, surrounding zinc continues to protect the exposed steel by corroding or sacrificed. This sacrificial nature of zinc is one of the critical factors in prolonging the service life of galvanized steel products.

Advantages of Galvanized Steel in Construction

Galvanized steel has a large number of advantages when it comes to construction, allowing for the enhancement of durability and dependability in the structures. A few important advantages can be tabulated as under:

- Extended Service Life of Materials: Galvanization can substantially increase the service life of building materials. The zinc coating protects steel from rust for many years, reducing frequent repairs or replacement. This durability makes galvanized steel economically attractive in large-scale construction projects and infrastructure development.

- Low Maintenance Costs: Galvanized steel requires minimum maintenance on account of its resistance to corrosion. This is in contrast to other materials, which often go through many coats of repainting, sealing, or treatment to stop rust. Galvanized steel sustains strength and integrity with essentially such little upkeep. For this reason alone, the low maintenance translates into respective cost savings throughout a structure's lifetime.

- Versatility in Application: Galvanized steel is a pretty versatile material that can be used in everything from roofing and fencing to structural beams and reinforcement bars. Its resistance to corrosion extends its use from indoor to outdoor applications, including areas with extreme weather conditions or corrosive agents like saltwater.

- Environmental Benefits: The fact that galvanized steel is durable, thereby not frequently needing replacements, increases sustainability in conserving resources. Galvanized steel is completely recyclable, meaning the galvanizing process does not harm the environment. Employing the use of longer-lived materials and recyclable ones decreases the carbon footprint emanating from a construction project in its entirety.

Galvanizing Process: Hot-Dip versus Electro-Galvanizing

The two major galvanizing processes for steels are: hot-dipping galvanization and electro-galvanization. Each technique has especial advantages and is selected based on the particular needs of the job.

Hot-dip Galvanization

Hot-dip galvanizing involves dipping steel pieces in a bath of molten zinc at approximately 450°C, with up to ±25°C variation. From this process, thick, tough coatings are attained that offer very good corrosion resistance. This zinc coating, though variable in thickness, generally gives good protection in outdoor use and in in-exposure to air characterized by humidity or salt mist.

Electro-Galvanisation

On the other hand, electro-galvanization is a technique of applying zinc by an electrochemical means. This produces a thin and uniform coating applied where the ornamentation is to be used indoors or wherever the chances of corrosion are limited. The areas where this can be effectively used include car parts, household appliances, and other areas where good looks with the exact thickness of coats are highly required.

Applications of Galvanized Steel within Construction

Galvanized steel is widely used in many fields of construction due to its resistance to corrosion. The usual uses are:

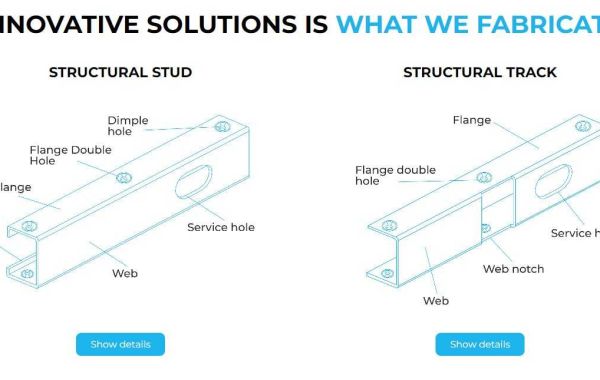

- Structural Steel Frames: Galvanized steel is very much in use in the structural framing of building construction. Strength and rust opposition amalgamate in steel to provide a strong and long-lasting framework to the buildings. This application comes out most effectively in highly humid areas, or wherever the buildings are exposed to sea air.

- Roofing and Siding: Galvanized steel is also very common for roofing and siding materials. Its resistance to bad weather, heavy rain, snow, and also extraordinary changes in temperature is quite beneficial in protecting the building from these elements. Additionally, galvanized steel roofing and siding can last for many years without significant deterioration.

- Bridges and Infrastructure: Galvanization of steel is essential in infrastructure projects such as bridges, highways, and pipelines. This has made it reliable for very long service life with minimal maintenance, which in turn reduces the overall cost and downtime due to repairs and replacements for continuous operation of critical infrastructure.

Factors that Affect Service Life of Galvanized Steel

While galvanized steel exhibits excellent corrosion resistance, its service life is dependent upon several factors. Knowledge of these determining factors allows specification of the type and thickness of zinc coating for specific applications.

Environmental Conditions

Galvanized steel corrodes at a rate extremely susceptible to environmental conditions. Areas near the sea or highly industrially polluted can have rates of corrosion that could be quicker due to the presence of salts and chemicals. A hot-dip galvanizing to apply a thicker layer of zinc is recommended in these instances.

Mechanical Damage

Physical damage to the zinc coating may lead to scratches or abrasions that produce bare spots on the steel surface. These bare spots, of course, would be more prone to attack from an atmosphere, although some protection may still be derived from sacrificial corrosion of the surrounding zinc. More extensive damage offered by mechanical deterioration will compromise the integrity of the coating as a whole. The possibility of mechanical damage can be minimized by proper handling and installation techniques.

Thickness of Zinc Coating

The thickness of the zinc coating directly defines the durability of galvanized steel itself. Thicker coatings mean longer protection from corrosion, though the weight and probably the costs rise accordingly. Finding the right balance between offering protection and being economically wise in choosing that particular type of galvanized steel for a certain project is indispensable.

Conclusion: Durability of Galvanized Steel

Galvanized steel remains a backbone material in the construction industry due to the fantastic strength and corrosion resistance it possesses. The zinc coating elicits protection from the environment, but above all, extends service life through sacrificial protection of structural steel. Galvanized steel is a trusted and cost-effective guard for residential, commercial, and industrial applications against rust and corrosion. Understanding how zinc coating works and its benefits empowers construction professionals and the general public to make informed decisions regarding their choice of materials, which will afford safer, more durable, and sustainable structures.

FAQs

How does zinc coating on steel avoid rust?

The zinc coating acts as a physical barrier between the steel and moisture/oxygen, more or less essentially needed for rusting. Besides, zinc itself corrodes prior to the underlying steel, providing sacrificial protection even in the case when the coating is scratched or damaged.

What is the advantage of galvanized steel when used in construction?

Galvanized steel in construction possesses advantages like extended material life, reduced maintenance costs, versatility in applications, and environmental benefits. It assures the corrosion resistance of the structure for durability and safety with time and reduction frequency repairs or replacements.

What is the difference between hot-dip galvanization and electro-galvanization?

Hot-dipping galvanizing means immersion in molten zinc, with the result that thick and durable coatings are obtained to be highly resistant during outdoor exposure, even under severe conditions. Electro-galvanizing is an electro-chemical process offering a thin layer coating of zinc, recommended for indoor application and also for products where a good look with uniformity is required.

Galvanized steel can be used in sea/coastal areas.

Yeah, it is possible to use galvanized steel in areas along coasts. One would think that due to the increased salt content and humidity that could accelerate atmospheric corrosion, thicker zinc coatings should be chosen. Indeed, hot-dip galvanizing is very frequently recommended for these conditions just because of its thicker coating against longer life.

How long does galvanized steel last?

The life of galvanized steel further depends on prevailing environmental conditions and the thickness developed in the zinc coating. In a general estimation, the life of galvanized steel could range anywhere from 20 to 50 years or more in most environments. In less corrosive environmental conditions, it can last even longer.

Galvanized steel: Is it green-friendly?

Galvanized steel is an environmentally friendly product: long-life performance cuts resource consumption and replacement needs. Galvanized steel is fully recyclable, and the galvanizing process has relatively low environmental impacts compared to other corrosion protection methods.