Chamfers and Radii: What’s the distinction?

Adding chamfers or radii to a component’s edges is a smart way to enhance in shape, take away unsafe edges, and beautify the part’s aesthetic appeal. So, what’s the distinction between chamfer and radii(fillet):

Chamfers. A chamfer is a forty-five-diploma bevel cut across adjacent right angles. Chamfers are frequently used to create clearance for mating or connecting parts. We frequently add chamfers to brackets, enclosures, and faceplates. Chamfers also can simplify the challenge of manually positioning components in the course of assembly, and they prevent injury by way of doing away with sharp edges. (Technically speaking, the handiest corners reduced to forty-five stages are called chamfers, although the terms “bevel” and “chamfer” are often used interchangeably.)

Radii. A radius replaces a raw nook with a rounded side instead of a chamfered part. Engineers normally layout radii to improve a component’s safety and decorate its appearance, though, like chamfers, radii can also enhance the meeting and shape of mating or connecting components.

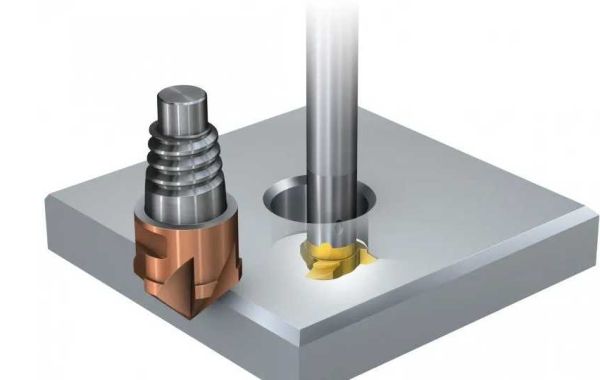

Attaining chamfers and radii

ASM can acquire chamfers and radii with the use of numerous methods, inclusive of unique punch equipment, hand-submitting, or shaping with a twin-motion sander. Tumbling can be an effective manner of including a radius for your component’s edges. For chamfered and rounded edges with vital tolerances, however, machining is nearly usually the satisfactory—and only—solution.

Secure Edges and smooth assembly

whilst greater safety and simplified assembly are critical in your sheet metal parts, either chamfers or radii will do the trick. You don’t even want to dimension those functions to your print or encompass them in your version. In reality, don’t dimension your edges—or we’ll quote you for critical dimensions you don’t really want!

you can further your savings by putting off the non-vital chamfers and radii out of your 3D version, too. in case you don’t do it, we ought to cast off these design factors before programming our machines.

Safety, simplified

if your sole purpose is protection, the simplest manner to get your component’s sharp edges removed is to invite. just upload a note for your print asking us to “eliminate all sharp edges”—and we can.

At ASM, deburring is protected as part of our fashionable techniques, so if safety is your simplest recognition, deburred metal edges are usually considered sufficiently smooth.

Way to get chamfers and radii with crucial dimensions

whilst we see that you’ve dimensioned the chamfers and radii to your print, we agree that the one's dimensions are vital and that you’ll check out your elements according to the one's dimensions.

To ensure precision and accuracy, we’ll have interaction with our CNC system save to machine the chamfers or radii. although machining does add to a part’s value and lead time, it’s the first-rate process for attaining essential side specifications and stopping part rejections at some stage in inspection.