Regardless of future technologies, formed components are still manufactured by hand. Metal is their canvas. It is the company's metal expression that is defined.

His film camera arrived. Their was only one camera. Film, metering, and focus It got me thinking about sheet metal forming.

Photography hasn't changed in almost a century. To focus an image, you must compose it, hold the camera still, comprehend its light values, expose the film or sensor properly, and focus. Photography increased exposure and focus. In the end, only the photographer's skill and understanding matter.

Metforming Now is the time for IoT and simulation. Technology aids the metal artist. Sometime it's good to ignore tech That's not heresy; it's history. The only constant is being.

Machines can execute repeating tasks without tiring. It may also collect statistics and suggest ways to enhance efficiency. This way they can learn from past mistakes. Technology can't replace the greatest workers.

A competitive edge. Affordability and quality attract clients. Metals have varying sales and profit potential. Technology aids workforce growth. Metal knowledge affects employee performance.

Younger individuals are buying used print and film cameras, increasing sales. Originality, owner's ability to express themselves, and non-digital tool convenience are all variables.

It's a dull world. However, Etsy, Amazon Handmade, and other craft businesses affirm our desire for something unique.

So we can avoid the fake news. The buying public suspects and dislikes false models. We make sheet metal parts in bulk. Our talent makes us distinct. Our knowledge and skills enable us to meet market expectations.

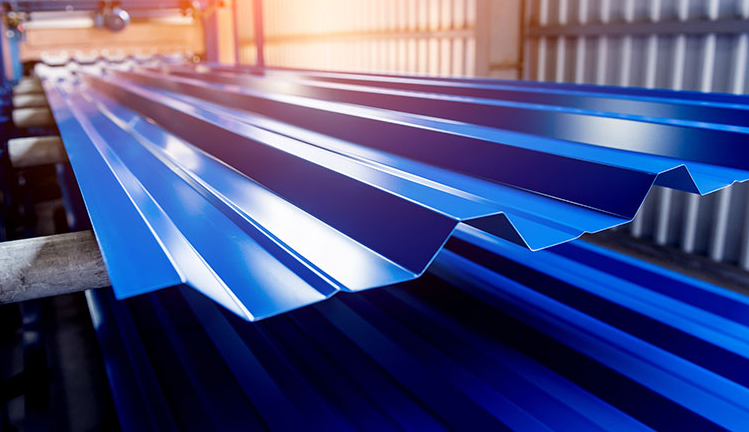

It involves forcing a flat metal piece into a permanent shape. Flat metal is a hinge or a plane part. The metal, the technique, and the ability required to mold it vary.

Photographing certain materials requires inks. Ink absorption and glossiness alter the final image. Knowing your metal's mechanical properties will help you predict press behavior. This knowledge may aid in lubricant selection. Data collection helps enhance processes. But effective business judgment is yours.

Today's technologies are fantastic. For a great component, you must understand variables. Hardware, software and networking technologies will be obsolete in 4–7 years. Production obsolescence jeopardizes operations, security. Skills development ensures productivity and efficiency.