Aluminum is an extraordinarily protean material. This measure of functionality would not be doable without the presence of different product styles. When it comes to aluminum shaping, there are two popular styles drawn and extruded.

Both processes involve using a bones or earth, and follow identical product guidelines aluminum is shaped into a billet and cut to a specific length. But that’s enough much where the parallels end. Drawn and extruded aluminum each possesses unique characteristics and rates with value- added benefits for your business.

When it’s time to submit an RFQ for your coming aluminum design, what are some effects you should consider with drawn or extruded aluminum? We ’ve collected a list of questions and answers laying out the pros, the cons and main differences between the two styles to insure you get the stylish result.

How does the drawn aluminum process work?

As we mentioned, aluminum is curated into a shape with heat and involves a earth or die depression. Drawn aluminum follows suit, but with a significant crucial difference plastic distortion.

In this process, when aluminum is forced through a bones, it’s stretched out to the form of the asked part, also pushed through a alternate bones, witnessing what's known as cold delineation or deep freeze working. The capability to permanently distort a material to compressive, bending or torsion stresses is called plastic distortion. This point of the process is when the final confines of the product are determined.

Which operations work best with drawn aluminum?

Intricate or indirect objects similar as barrels, tubes, pots and kissers; drawn aluminum is ideal for products taking tight forbearance and thin walls, icing structural integrity and predictable performance under pressure.

drawn aluminum shapes

Are there any excrescencies with drawn aluminum tubing?

It ca n’t be stressed enough the significance of knowing the malleability of aluminum before beginning theprocess.However, it becomes brittle and fragile, and eventually gashes, If the material is pulled too important. So, be aware of aluminum grade, alloying rudiments and strengthening process when going with drawn aluminum.

What's extruded aluminum?

Aluminum extrusion is the system of forcing aluminum through a shaped opening in a bones or earth, producing a asked configuration of the final product. To fantasize the operation, suppose of children’s modeling complexion. It comes with a shape tool tackle featuring different molds and biographies. Elect a specific profile; push the complexion through the uniquely shaped hole and eschewal comes the prognosticated shape – hence, extruded aluminum.

How does the aluminum extrusion process differ from drawn aluminum?

The extruded aluminum system begins with hotting the material to a high temperature. Once the aluminum is soft and malleable, it’s forced through the bones. The difference between aluminum extrusion and drawn aluminum is temperature. As we stated, drawn applies cold delineation, which is conducted at room temperature, rather than at a veritably high temperature.

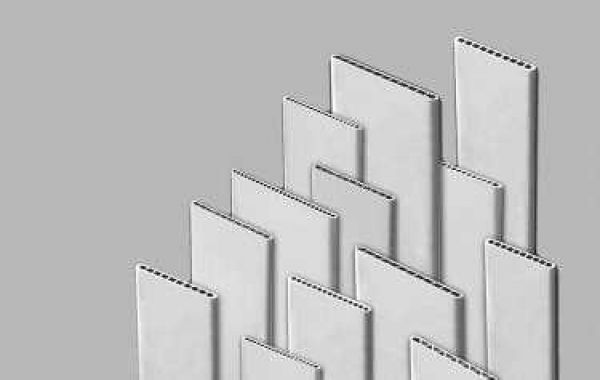

Which products are stylish for extruded aluminum?

With drawn aluminum, the stylish results are produced for small, detailed and round factors. For extruded aluminum, there’s a considerable capacity to shape colorful operations, similar as classes, tubing, doors, window frames, rail and much further.

With costs, which process is the better bargain?

.

Cold delineation is more complex and involves an expansive collection of tools and accoutrements to insure the drawn aluminum process is completed effectively. Aluminum extrusion can achieve briskly manufacturing with affordable tooling and lower material waste. On average, you can anticipate to pay lower for extruded aluminum than drawn aluminum. Still, it all depends on the shape you're trying to produce.

There you have it – answers to the most important questions regarding drawn and extruded aluminum. Ready to begin your coming aluminum design? Maybe you have a many further questions you like answered? At Star Extruded Shapes, we're your complete aluminum extrusion provider with turnkey results for all of your design needs. Let’s talk moment about taking your aluminum design to the coming position.