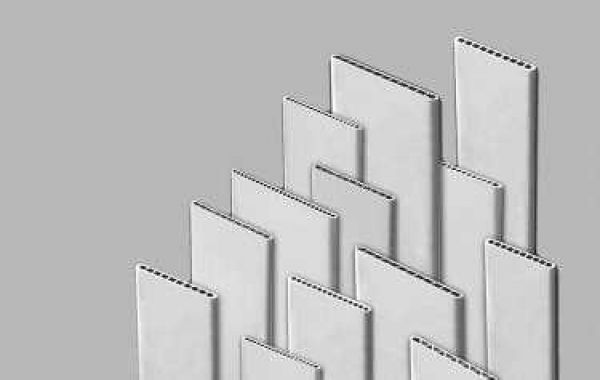

According to its producing process, Fin tube heat exchangers can classify their fin tubes into integral fin tubes, welded fin tubes, high- frequence welded fin tubes, and mechanically connected fin tubes.

- The integral fin tube is made by casting, machining or rolling. The fin and the tube are integrated.

- Welded fin tubes are substantially manufactured by processes similar as brazing or inert gas shielded welding. The ultramodern welding process can connect the fins of different accoutrements, and can make the fin tube simple, provident, and has good heat transfer and mechanical parcels. Because the residue in the weld isn't conducive to heat transfer and may beget fracture, so the quality of the welding process should be paid attention to when producing similar fin tubes.

- The high- frequence welding fin tube substantially uses the high- frequence electrical induction generated by its high- frequence creator, so that the face of the tube and the fins can be exposed to high temperature, and the two can be melted within a range of about 10 μm. The pressure connects the fins to the tube. No flux and no solder, simple manufacturing, high productivity, excellent heat transfer and mechanical parcels.

- The fin tube heat exchanger substantially adopts its mechanical connection. When it's used, it generally adopts three types of its crack distance type, mosaic type, sleeve type or string type. The finned fin tube is simple to manufacture. The essence band is mechanically or welded around one end of the tube. The essence band is tightly wound on the external wall of the tube by the necklace of the tube. The other end is fixed to form a finned fin tube. The material of the winding distance may be bobby vid, sword vid or aluminum vid.