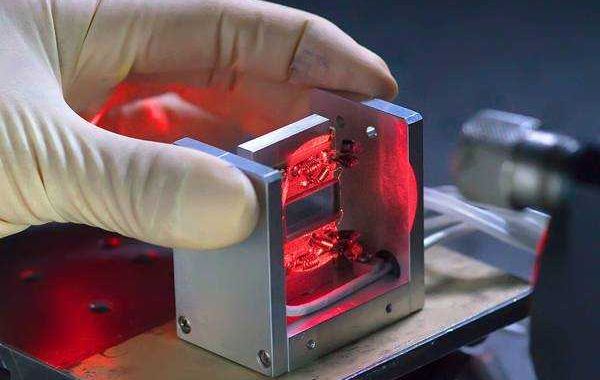

Acousto-optic modulators (AOMs) are integral components of optical systems, offering precise control over light modulation. However, like all technologies, they are subject to issues that can hinder performance. Understanding these common problems and their solutions is essential for maintaining optimal AOM functionality. This article presents a comprehensive guide to troubleshooting AOMs, focusing on damage prevention, noise diagnosis, and effective maintenance strategies.

Preventing Damage to AOMs

- Power Management: Excessive power is a leading cause of AOM failure. To prevent damage, it's vital to operate AOMs within specified power limits. Monitoring power levels and employing management strategies can significantly extend AOM lifespan.

- Environmental Considerations: AOMs are sensitive to environmental factors like temperature, humidity, and vibrations. Housing AOMs in stable environments and utilizing vibration-damping mounts can help mitigate damage risks.

- Optical Alignment: Proper optical alignment is crucial to avoid unnecessary stress on the AOM. Misalignment can increase diffraction losses and lead to potential damage. Regularly checking and adjusting the optical path is essential for optimal performance.

Diagnosing Noise Issues

- Identifying Noise Sources: Noise in AOMsystems can stem from various sources, including electrical interference, mechanical vibrations, and thermal fluctuations. Pinpointing the root cause is essential for effective troubleshooting.

- Signal Integrity: Noise can compromise the modulation signal's integrity. Using high-quality signal cables and connectors can reduce electrical noise, while proper grounding techniques help minimize interference.

- Acoustic Noise: Mechanical vibrations can also impact AOM performance. Regularly checking for noise sources and employing isolation measures can help mitigate these issues, enhancing overall performance.

Maintenance Strategies

- Regular Inspections: Conducting routine inspections of AOMs and associated components can identify potential issues early. This includes examining optical elements, verifying alignment, and checking electrical connections.

- Calibration: Periodic calibration of AOM systems is crucial for maintaining accurate performance. Calibration ensures modulation characteristics stay within specified parameters, enhancing system reliability.

- Documentation: Keeping detailed records of AOM performance, troubleshooting efforts, and maintenance activities is beneficial for long-term management. This documentation aids in identifying trends and recurring issues, allowing for proactive measures.

Conclusion

Effective troubleshooting of AOMs requires a thorough understanding of common issues and proactive strategies for damage prevention, noise diagnosis, and maintenance. By adhering to best practices, users can enhance the longevity and performance of AOM systems. Regular inspections, calibration, and attention to environmental factors are essential for ensuring optimal performance across various applications.