Armodafinil, a popular wakefulness-promoting drug, is widely used in the treatment of conditions like narcolepsy, sleep apnea, and shift work sleep disorder. As a pharmaceutical product, its demand has grown globally due to its effectiveness in helping people manage excessive sleepiness and improve cognitive performance. For pharmaceutical companies involved in the production of armodafinil, understanding and optimizing Armodafinil Production Cost is crucial for maintaining profitability and remaining competitive in the pharmaceutical market.

Request a Free Sample for Armodafinil Production Cost Reports – https://www.procurementresource.com/production-cost-report-store/armodafinil/request-sample

In this article, we’ll explore the key factors influencing armodafinil production costs and how businesses can improve cost-efficiency, leveraging insights from Procurement Resource’s Armodafinil Production Cost Reports.

Why Armodafinil is Important

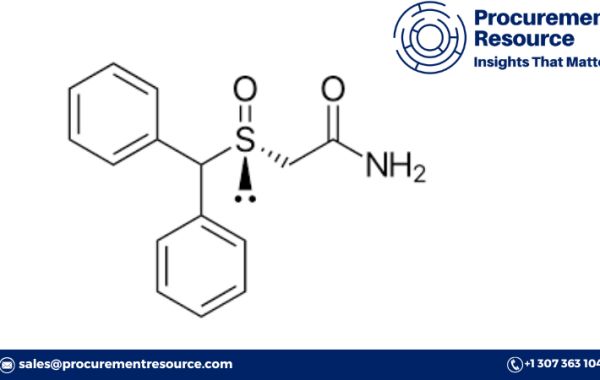

Armodafinil is a highly sought-after medication, particularly in the realm of sleep disorders. It is an enantiopure version of modafinil, meaning it contains only one of the enantiomers (R-enantiomer) of modafinil, making it more potent and longer-lasting in its effects. Beyond its clinical uses, armodafinil has also been used off-label to improve focus, alertness, and mental acuity in high-performance environments.

As demand for smart drugs and effective treatments for sleep disorders continues to rise, pharmaceutical companies are under pressure to manage production costs while maintaining high quality and regulatory compliance. Understanding the underlying cost components of armodafinil production is essential for companies looking to optimize efficiency and reduce expenses.

Key Factors Influencing Armodafinil Production Costs

The cost of producing armodafinil depends on several critical factors, including raw material inputs, manufacturing processes, energy consumption, labor, regulatory compliance, and quality control. Below is a detailed breakdown of the major cost drivers associated with the production of armodafinil:

Read the Full Report – https://www.procurementresource.com/production-cost-report-store/armodafinil

1. Raw Material Costs

Armodafinil is synthesized through a complex chemical process, requiring specific raw materials and intermediates. The availability and cost of these chemical inputs can fluctuate based on supply and demand, geopolitical events, and market conditions in the pharmaceutical industry.

Active Pharmaceutical Ingredients (APIs): The API for armodafinil must be produced or procured from specialized suppliers. The synthesis of armodafinil involves multiple steps, and each stage requires specific chemicals, reagents, and catalysts. Variations in the cost of these raw materials directly impact the overall production cost of the drug.

Solvents and Reagents: The production of armodafinil requires solvents for extraction, purification, and crystallization processes. Any fluctuations in the cost of these chemicals, as well as the cost of purifying and recycling solvents, can influence production expenses.

2. Manufacturing Processes

The manufacturing of armodafinil involves several steps, including chemical synthesis, purification, crystallization, drying, and formulation into a consumable form (typically tablets or capsules). Each step requires specialized equipment, technical expertise, and strict adherence to Good Manufacturing Practices (GMP).

Process Efficiency: Optimizing production efficiency is critical to controlling costs. Any inefficiencies in the production process, such as lower yields, longer cycle times, or excessive waste, can drive up manufacturing costs.

Technological Upgrades: Investing in modern technologies, such as advanced reactor systems or automation equipment, can improve production efficiency and reduce labor and operational costs. However, these upgrades require significant capital investment, which must be balanced against the long-term savings they offer.

3. Energy and Utility Costs

Like many pharmaceutical products, the production of armodafinil is energy-intensive. Maintaining the necessary conditions for chemical reactions, purification processes, and quality control procedures requires large amounts of electricity and steam.

Heating and Cooling Requirements: Maintaining the precise temperatures required for chemical reactions and solvent recovery during the synthesis of armodafinil consumes a significant amount of energy. Optimizing these energy requirements can lead to substantial cost savings.

Utility Management: Efficient management of utilities, such as water and gas, is also necessary to reduce overall production costs. Implementing energy-efficient technologies and closely monitoring energy consumption can help reduce costs.

4. Labor and Operational Costs

Labor is a major component of armodafinil production costs. Skilled workers, including chemists, engineers, and quality control specialists, are required to oversee the production process, ensure adherence to GMP standards, and maintain high-quality outputs.

Labor Costs by Region: Labor costs vary significantly by region, and companies operating in areas with higher wages may face higher production costs. In such cases, automation and process optimization can help reduce the reliance on manual labor and improve cost-efficiency.

Operational Costs: Routine operations, including equipment maintenance, waste disposal, and facility management, also contribute to the overall cost of production. Minimizing downtime, optimizing production schedules, and improving workflow efficiency can help reduce operational expenses.

5. Quality Control and Regulatory Compliance

Given the pharmaceutical nature of armodafinil, strict regulatory requirements govern its production. Ensuring compliance with FDA, EMA, and other regulatory bodies’ standards adds to production costs. Quality control testing must be rigorous, with batches undergoing extensive testing for purity, potency, and safety before release.

- Compliance Costs: Maintaining GMP certification and compliance with evolving regulations requires continual investment in quality assurance personnel, facilities, and monitoring systems. Failure to meet these standards can result in fines, recalls, or delays, all of which can increase overall costs.

6. Environmental and Sustainability Considerations

Pharmaceutical companies are under increasing pressure to minimize their environmental impact. Waste management, emission controls, and sustainable sourcing of raw materials are essential elements of armodafinil production.

Waste Management: Proper disposal of chemical waste from the production of armodafinil is crucial for minimizing environmental damage. Implementing green chemistry practices, recycling solvents, and reducing by-products can help lower costs while improving sustainability.

Sustainability Initiatives: Companies that invest in sustainable production methods, such as energy-efficient equipment or renewable energy sources, may incur higher upfront costs but benefit from long-term savings and a positive brand image.

How Procurement Resource’s Armodafinil Production Cost Reports Can Help

At Procurement Resource, we provide detailed Armodafinil Production Cost Reports that give businesses insights into every aspect of the production process, from raw material procurement to regulatory compliance. Our reports are designed to help pharmaceutical companies optimize their production processes, reduce costs, and improve operational efficiency.

Ask an Analyst – https://www.procurementresource.com/production-cost-report-store/armodafinil/ask-an-analyst

Here’s how our reports can benefit you:

1. In-Depth Cost Breakdown

Our reports offer a comprehensive breakdown of the costs involved in armodafinil production, covering raw materials, labor, energy, and operational expenses. By understanding the key cost drivers, businesses can identify areas for potential savings and efficiency improvements.

2. Real-Time Data and Market Trends

The pharmaceutical industry is constantly evolving, and our reports include up-to-date data on market trends, pricing fluctuations, and regulatory changes. By staying informed about the latest developments, companies can make better decisions about procurement and production strategies.

3. Benchmarking and Efficiency Analysis

We provide benchmarking data that allows businesses to compare their production costs against industry standards. This helps identify areas where you may be able to improve efficiency, reduce waste, or adopt new technologies to lower production expenses.

4. Customized Solutions

Our reports are fully customizable, allowing you to focus on the specific cost factors that are most relevant to your business. Whether you’re looking to streamline production, optimize energy use, or reduce waste, our tailored solutions provide the insights you need to succeed.

Conclusion: Optimizing Armodafinil Production Costs for Success

The production of armodafinil involves several cost factors, from raw material inputs to energy consumption and regulatory compliance. By gaining a deeper understanding of these cost drivers, pharmaceutical companies can identify opportunities for cost reduction and efficiency improvements. At Procurement Resource, our Armodafinil Production Cost Reports provide actionable insights that help businesses stay competitive in the pharmaceutical market.

Request Your Free Sample Report Today:

If you're ready to optimize your armodafinil production costs, we invite you to request a free sample of our Armodafinil Production Cost Report from Procurement Resource today.

Request a Free Sample – https://www.procurementresource.com/production-cost-report-store/armodafinil/request-sample

Contact Us

Company Name: Procurement Resource

Contact Person: Amanda Williams

Email: sales@procurementresource.com

Toll-Free Numbers:

USA Canada: +1 307 363 1045

UK: +44 7537171117

Asia-Pacific (APAC): +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA