To mitigate these limitations and achieve accurate delay measurements, consider the following tips:

Calibration

- Regularly calibrate the MADL using a calibrated delay source or interferometer.

- This ensures that the device's delay readings are accurate and consistent.

Temperature Control

- Maintain a stable temperature environment to minimize thermal expansion effects on the fiber.

- Temperature fluctuations can introduce unwanted delay variations.

Vibration Isolation

- Isolate the MADL from vibrations to prevent unintended delay fluctuations.

- Vibration can cause mechanical instability and affect the fiber's length.

Proper Handling

- Avoid excessive force or bending of the fiber, which can introduce unintended delays and polarization changes.

- Handle the fiber carefully to minimize stress.

Slow and Steady Adjustments

- Make slow and steady adjustments to the delay mechanism to avoid overshooting the desired delay.

- Rapid adjustments can introduce mechanical vibrations and inaccuracies.

Monitor Polarization State

- Use polarization-maintaining fiber and polarization-sensitive components to preserve the polarization state of the light.

- Monitor the polarization state at the output of the MADL to ensure that it remains stable.

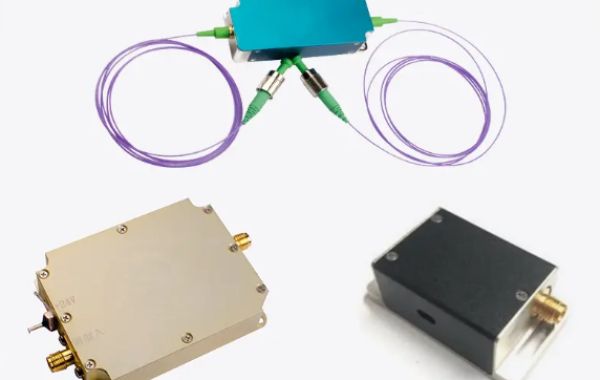

Use High-Quality Components

- Choose a MADL with high-quality components, such as precision-engineered spools and smooth adjustment mechanisms.

- High-quality components can improve the device's accuracy and reliability.

By following these guidelines, you can maximize the accuracy and reliability of your delay measurements with a manual adjustable fiber delay line.