DTH hammer And bit are essential tools in the drilling industry, widely used for various applications such as mining, construction, and geothermal drilling. Their design and functionality make them ideal for penetrating hard rock formations with precision and efficiency.

The DTH hammer works by delivering impact energy to the bit, which crushes the rock into smaller fragments. Unlike top-hammer drilling methods, the impact source in a DTH system is located near the bottom of the drill string. This proximity ensures minimal energy loss, allowing for deeper and straighter holes.

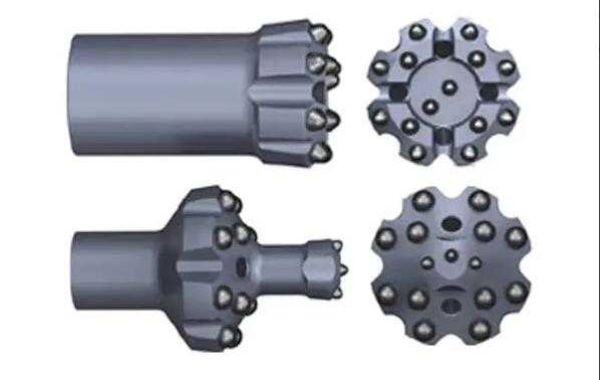

The bit is another crucial component of the system. Manufactured with high-grade materials and designed with specific patterns, the bit determines the drilling speed, hole size, and the type of rock it can penetrate. Common types of DTH bits include convex, concave, and flat face designs, each suited to particular drilling needs.

A major advantage of the DTH system is its adaptability. Operators can select hammers and bits according to the geological conditions they encounter. Furthermore, these tools are designed for easy maintenance, ensuring prolonged operational life.

When selecting a DTH hammer and bit, several factors must be considered, including the required hole diameter, depth, and the type of material being drilled. Proper care and timely replacement of worn parts can significantly enhance the performance of the system. As a result, DTH tools remain a reliable choice for industries needing precise and durable drilling solutions.